Aerodynamic engineers play a crucial role in the design and optimization of vehicles, aircraft, and various other structures that interact with air. Their primary responsibility is to analyze and improve the aerodynamic performance of these entities, ensuring that they move efficiently through the atmosphere. This involves a deep understanding of fluid dynamics, physics, and material science.

Aerodynamic engineers utilize their expertise to minimize drag, enhance lift, and improve overall stability, which are essential factors in achieving optimal performance and fuel efficiency. The work of an aerodynamic engineer is multifaceted, often requiring collaboration with other engineering disciplines such as mechanical, structural, and electrical engineering. They must be adept at using advanced simulation tools and methodologies to predict how air flows around objects.

This predictive capability is vital for making informed design decisions early in the development process. Additionally, aerodynamic engineers must stay abreast of the latest research and technological advancements in their field to apply innovative solutions to complex aerodynamic challenges.

Key Takeaways

- Aerodynamic engineers focus on designing vehicles and structures to minimize air resistance and maximize performance.

- Aerodynamics plays a crucial role in the design of vehicles, buildings, and even sports equipment.

- Computational Fluid Dynamics (CFD) allows engineers to simulate and analyze airflow over complex shapes and structures.

- Wind tunnel testing is essential for validating CFD simulations and fine-tuning aerodynamic designs.

- Integrating aerodynamics into vehicle design can improve fuel efficiency and overall performance.

The Importance of Aerodynamics in Design

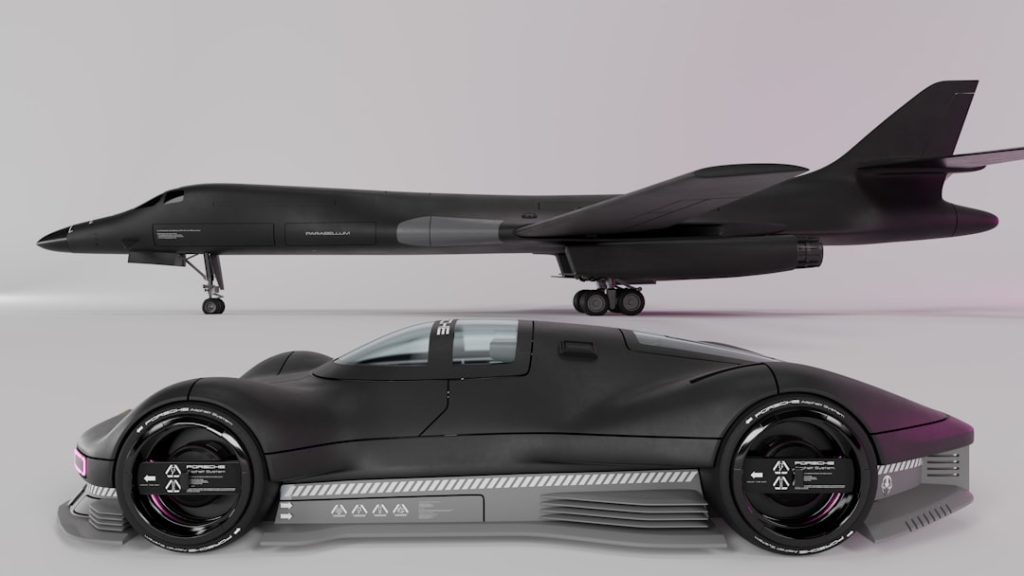

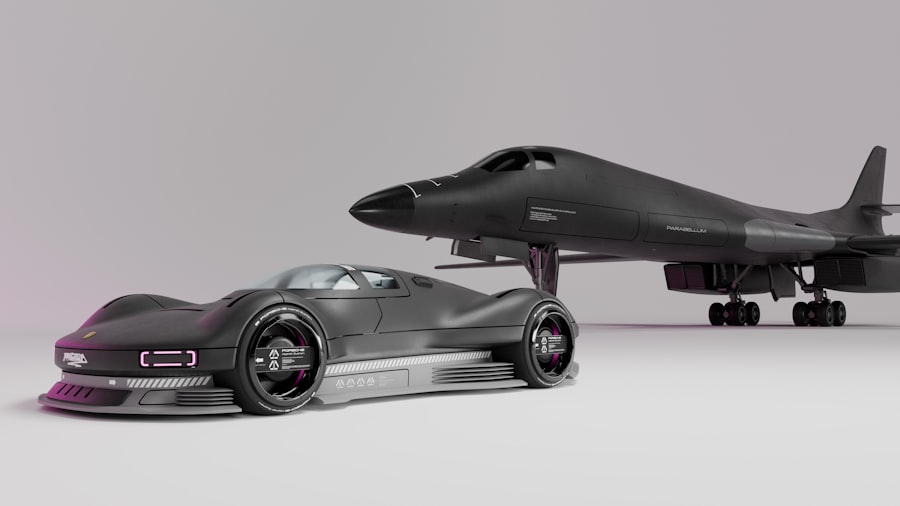

Aerodynamics is a fundamental aspect of design across various industries, particularly in automotive and aerospace engineering. The principles of aerodynamics dictate how air interacts with moving objects, influencing factors such as drag, lift, and stability. In the automotive sector, for instance, a vehicle’s aerodynamic profile can significantly affect its fuel efficiency and performance.

A well-designed car can reduce drag by streamlining its shape, allowing it to cut through the air more effectively. This not only enhances speed but also contributes to lower emissions and improved fuel economy. In aerospace applications, the importance of aerodynamics is even more pronounced.

Aircraft must be designed to withstand the forces of lift and drag while maintaining stability during flight. The shape of an aircraft’s wings, fuselage, and tail are meticulously crafted to optimize airflow and ensure safe operation at various speeds and altitudes. The consequences of neglecting aerodynamic principles can be severe, leading to increased fuel consumption, reduced performance, and even catastrophic failures.

Thus, understanding and applying aerodynamic principles is essential for engineers tasked with designing efficient and safe vehicles.

Utilizing Computational Fluid Dynamics (CFD) in Aerodynamic Engineering

Computational Fluid Dynamics (CFD) has revolutionized the field of aerodynamic engineering by providing powerful tools for simulating fluid flow around objects. CFD allows engineers to visualize airflow patterns, pressure distributions, and other critical parameters that influence aerodynamic performance. By employing numerical methods and algorithms, CFD can model complex interactions between air and surfaces with remarkable accuracy.

This capability enables engineers to conduct virtual experiments that would be impractical or impossible to perform in real life. The application of CFD in aerodynamic engineering extends beyond mere visualization; it serves as a critical decision-making tool throughout the design process. Engineers can iterate on designs quickly by modifying parameters and observing the effects on airflow characteristics.

For example, in the automotive industry, CFD can be used to test various body shapes or wing configurations without the need for physical prototypes. This not only accelerates the design cycle but also reduces costs associated with material waste and manufacturing. As computational power continues to grow, the fidelity of CFD simulations improves, allowing for even more detailed analyses that can lead to groundbreaking advancements in aerodynamic design.

The Role of Wind Tunnel Testing in Aerodynamic Engineering

| Wind Tunnel Testing Metrics | Description |

|---|---|

| Drag Coefficient | The measure of the drag force on an object in a fluid flow, used to assess aerodynamic performance. |

| Lift Coefficient | The measure of the lift force on an object in a fluid flow, used to evaluate the lift generation of an aircraft wing. |

| Pressure Distribution | The mapping of pressure over the surface of an object, providing insights into flow behavior and aerodynamic forces. |

| Flow Visualization | The observation and analysis of flow patterns around an object, aiding in understanding aerodynamic phenomena. |

| Model Scaling | The process of scaling down a physical model to represent full-scale aerodynamic behavior, allowing for cost-effective testing. |

While CFD has become an indispensable tool in aerodynamic engineering, wind tunnel testing remains a vital component of the design validation process. Wind tunnels provide a controlled environment where engineers can observe real-time airflow around scaled models or full-sized prototypes. This empirical data is crucial for verifying the accuracy of CFD simulations and ensuring that designs perform as expected under actual conditions.

Wind tunnel testing allows for the measurement of forces acting on a model, such as lift and drag coefficients, which are essential for evaluating aerodynamic efficiency. The process of wind tunnel testing involves creating a scale model of the object being studied and placing it within a tunnel where air is blown at controlled speeds. Engineers can manipulate various parameters such as angle of attack and flow speed to gather comprehensive data on how the model behaves under different conditions.

For instance, in aerospace applications, wind tunnel tests are critical for assessing an aircraft’s performance during takeoff and landing phases. The insights gained from these tests inform design modifications that enhance safety and efficiency before full-scale production begins.

Integrating Aerodynamics into Vehicle Design

Integrating aerodynamics into vehicle design requires a holistic approach that considers not only the external shape but also internal components that may affect airflow. For automotive engineers, this means collaborating closely with designers to create vehicles that are not only aesthetically pleasing but also aerodynamically efficient. Features such as spoilers, diffusers, and underbody panels can significantly influence airflow around a vehicle, reducing drag and improving stability at high speeds.

In addition to external features, engineers must also consider how components like wheels and mirrors interact with airflow. For example, wheel designs that minimize turbulence can contribute to overall aerodynamic efficiency. Furthermore, advancements in materials science allow for the use of lightweight materials that do not compromise structural integrity while enhancing performance.

By integrating aerodynamic principles throughout the design process—from initial sketches to final production—engineers can create vehicles that excel in both performance and efficiency.

Advancements in Aerodynamic Engineering Technology

The field of aerodynamic engineering is continuously evolving due to advancements in technology and materials science. Innovations such as additive manufacturing (3D printing) have opened new avenues for creating complex geometries that were previously difficult or impossible to achieve with traditional manufacturing methods. This technology allows engineers to produce lightweight components with intricate designs that optimize airflow while maintaining structural integrity.

Moreover, developments in sensor technology have enhanced the ability to gather real-time data on aerodynamic performance during testing phases. Sensors embedded within models can provide valuable insights into pressure distributions and flow characteristics that were once challenging to measure accurately. These advancements enable engineers to refine their designs based on empirical data rather than relying solely on theoretical models or simulations.

As technology continues to progress, the potential for breakthroughs in aerodynamic efficiency becomes increasingly promising.

Collaborating with Other Engineering Disciplines for Optimal Efficiency

Aerodynamic engineering does not exist in isolation; it requires collaboration across various engineering disciplines to achieve optimal results. For instance, mechanical engineers may work alongside aerodynamic engineers to ensure that structural components can withstand aerodynamic forces without compromising performance. Electrical engineers may also play a role in integrating advanced control systems that enhance stability and maneuverability based on real-time aerodynamic data.

This interdisciplinary approach fosters innovation by combining diverse perspectives and expertise. For example, when designing an electric vehicle (EV), aerodynamic engineers must collaborate with battery engineers to ensure that the vehicle’s shape accommodates battery placement while maximizing efficiency. Such collaboration leads to holistic solutions that address multiple aspects of vehicle performance simultaneously, resulting in designs that are not only aerodynamically efficient but also technologically advanced.

The Future of Aerodynamic Engineering: Sustainable and Eco-Friendly Solutions

As global awareness of environmental issues grows, the future of aerodynamic engineering is increasingly focused on sustainability and eco-friendly solutions. Engineers are tasked with developing designs that minimize energy consumption while maximizing performance. This shift is particularly evident in the automotive industry, where manufacturers are exploring electric vehicles (EVs) and hybrid technologies that require careful consideration of aerodynamics to enhance range and efficiency.

Innovative approaches such as biomimicry—drawing inspiration from nature—are gaining traction in aerodynamic design. For instance, studying how certain animals move through air can lead to insights into creating more efficient shapes for vehicles or aircraft. Additionally, advancements in renewable energy sources are prompting engineers to explore how aerodynamics can contribute to energy generation through wind turbines or other technologies that harness natural forces.

In conclusion, the future of aerodynamic engineering holds immense potential for creating sustainable solutions that address both performance needs and environmental concerns. As technology continues to advance and interdisciplinary collaboration becomes more prevalent, engineers will be better equipped to tackle the challenges posed by climate change while pushing the boundaries of what is possible in aerodynamics.