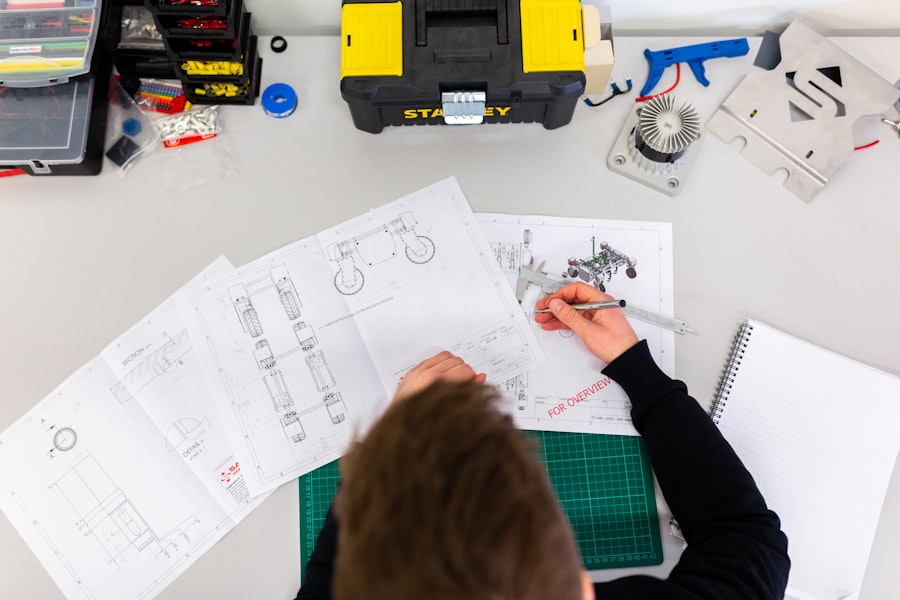

Mechanical and aerospace engineering are two intertwined disciplines that play a pivotal role in the advancement of technology and innovation. Mechanical engineering, often regarded as the broadest of the engineering fields, encompasses the design, analysis, manufacturing, and maintenance of mechanical systems. It draws upon principles of physics, mathematics, and material science to solve complex problems related to machinery and structures.

Aerospace engineering, on the other hand, is a specialized branch that focuses specifically on the development of aircraft and spacecraft. This field combines elements of mechanical engineering with additional considerations for aerodynamics, propulsion, and materials that can withstand extreme conditions. The significance of these engineering disciplines cannot be overstated.

They are foundational to numerous industries, including automotive, aviation, defense, and space exploration. As global challenges such as climate change and resource scarcity become more pressing, the role of mechanical and aerospace engineers is evolving. They are tasked with creating sustainable solutions that not only enhance performance but also minimize environmental impact.

The integration of advanced technologies such as artificial intelligence, machine learning, and additive manufacturing is reshaping the landscape of these fields, leading to innovative approaches that were previously unimaginable.

Key Takeaways

- Mechanical and Aerospace Engineering involves the design, development, and testing of mechanical systems and aerospace vehicles.

- Materials and Manufacturing Innovations play a crucial role in improving the performance and efficiency of mechanical and aerospace systems.

- Propulsion and Power Systems are essential for the movement and operation of aerospace vehicles and mechanical systems.

- Aerodynamics and Fluid Dynamics are important for understanding the behavior of air and fluids around mechanical and aerospace systems.

- Structural Design and Analysis are critical for ensuring the safety and reliability of mechanical and aerospace systems.

Materials and Manufacturing Innovations

The evolution of materials science has been a game-changer in mechanical and aerospace engineering. Traditional materials like steel and aluminum have been supplemented by advanced composites, ceramics, and smart materials that offer superior performance characteristics. For instance, carbon fiber reinforced polymers (CFRP) are increasingly used in aerospace applications due to their high strength-to-weight ratio and resistance to corrosion.

These materials allow for lighter aircraft designs that improve fuel efficiency and reduce operational costs. The use of titanium alloys is also prevalent in aerospace components where high strength and low weight are critical, particularly in engine parts and structural components. Manufacturing innovations have further transformed how engineers approach design and production.

Additive manufacturing, commonly known as 3D printing, has emerged as a revolutionary technique that enables the creation of complex geometries that were once impossible to achieve with traditional subtractive methods. This technology allows for rapid prototyping and customization, significantly reducing lead times in product development. For example, companies like GE Aviation have successfully utilized 3D printing to produce fuel nozzles for jet engines, resulting in parts that are not only lighter but also more efficient in terms of fuel consumption.

The ability to manufacture on-demand also opens up new possibilities for supply chain management, reducing waste and inventory costs.

Propulsion and Power Systems

Propulsion systems are at the heart of both mechanical and aerospace engineering, driving the performance of vehicles ranging from cars to spacecraft. In aerospace applications, propulsion technologies have evolved dramatically over the years. Traditional jet engines have been complemented by more advanced systems such as turbofan engines, which offer improved efficiency and reduced noise levels.

These engines utilize a combination of jet propulsion and fan-driven thrust to optimize performance across various flight regimes. The development of hybrid-electric propulsion systems is also gaining traction, promising to reduce emissions and fuel consumption in commercial aviation. In addition to conventional propulsion methods, the exploration of alternative power systems is reshaping the future of aerospace engineering.

Electric propulsion systems, including ion thrusters and electric ducted fans, are being investigated for their potential to provide efficient thrust with minimal environmental impact. NASA’s X-57 Maxwell project exemplifies this trend by developing an all-electric aircraft designed to demonstrate the viability of electric propulsion for regional air travel. Furthermore, advancements in battery technology are critical for the success of electric aircraft, as engineers strive to create lightweight batteries with higher energy densities that can sustain longer flights without compromising safety or performance.

Aerodynamics and Fluid Dynamics

| Category | Metric | Value |

|---|---|---|

| Aerodynamics | Lift Coefficient | 1.5 |

| Aerodynamics | Drag Coefficient | 0.3 |

| Fluid Dynamics | Reynolds Number | 5000 |

| Fluid Dynamics | Viscosity | 0.01 Pa·s |

Aerodynamics is a fundamental aspect of aerospace engineering that deals with the behavior of air as it interacts with solid objects, particularly aircraft and spacecraft. Understanding fluid dynamics is essential for optimizing designs to achieve maximum efficiency and performance. Engineers employ computational fluid dynamics (CFD) simulations to analyze airflow patterns around vehicles, allowing them to refine shapes for reduced drag and improved lift.

This computational approach has revolutionized the design process, enabling engineers to test multiple configurations virtually before committing to physical prototypes. The study of aerodynamics extends beyond traditional aircraft; it also encompasses the design of drones and unmanned aerial vehicles (UAVs). As these technologies gain popularity for applications ranging from delivery services to surveillance, understanding their aerodynamic properties becomes increasingly important.

For instance, engineers must consider factors such as stability, control surfaces, and weight distribution when designing UAVs to ensure they can operate effectively in various environmental conditions. The integration of biomimicry into aerodynamic design is another exciting development; by studying the flight patterns of birds or insects, engineers can derive insights that lead to more efficient aircraft designs.

Structural Design and Analysis

Structural integrity is paramount in both mechanical and aerospace engineering, where components must withstand extreme forces while maintaining safety and reliability. Engineers utilize advanced modeling techniques to analyze stress distributions within structures under various loading conditions. Finite element analysis (FEA) is a widely used method that breaks down complex structures into smaller elements for detailed examination.

This approach allows engineers to predict how materials will behave under different scenarios, ensuring that designs meet safety standards while optimizing weight. In aerospace applications, structural design must account for unique challenges such as fluctuating pressures during flight and thermal stresses during re-entry into the atmosphere. The use of lightweight materials is crucial in this context; however, engineers must balance weight reduction with structural strength.

For example, the Boeing 787 Dreamliner employs a composite fuselage that significantly reduces weight while maintaining structural integrity. Additionally, innovations in design methodologies such as topology optimization enable engineers to create structures that use material more efficiently by removing unnecessary mass while preserving strength.

Automation and Robotics

The integration of automation and robotics into mechanical and aerospace engineering has transformed manufacturing processes and operational capabilities. Automated systems enhance precision in production lines while reducing human error, leading to higher quality products at lower costs. Robotics plays a crucial role in assembly processes where components must be handled with care or where repetitive tasks can be automated for efficiency.

For instance, robotic arms are commonly used in aircraft assembly lines to perform tasks such as riveting or painting with remarkable accuracy. In aerospace applications, automation extends beyond manufacturing; it also encompasses flight operations through the development of autonomous systems. Unmanned aerial vehicles (UAVs) equipped with advanced sensors and artificial intelligence can perform complex missions without human intervention.

These technologies are being utilized for various purposes including agricultural monitoring, disaster response, and surveillance operations. The challenge lies in ensuring that these autonomous systems can operate safely alongside manned aircraft while adhering to regulatory frameworks.

Space Exploration and Satellite Technology

Space exploration represents one of the most ambitious frontiers for mechanical and aerospace engineering. The challenges associated with launching vehicles into space require innovative solutions across multiple domains including propulsion systems, materials science, and structural design. The development of reusable launch vehicles has been a significant advancement in this field; companies like SpaceX have pioneered technologies that allow rockets to return safely to Earth after delivering payloads into orbit.

This innovation not only reduces costs but also paves the way for more frequent space missions. Satellite technology has also seen remarkable advancements driven by mechanical and aerospace engineering principles. Satellites play a crucial role in communication, weather forecasting, navigation systems, and scientific research.

Engineers must consider factors such as orbital mechanics when designing satellites to ensure they can maintain their intended paths while withstanding harsh conditions in space. The miniaturization of satellite technology has led to the rise of small satellites or CubeSats that can be deployed at lower costs while still providing valuable data for various applications.

Future Trends and Challenges in the Field

As mechanical and aerospace engineering continues to evolve, several trends are shaping its future trajectory. One significant trend is the increasing emphasis on sustainability within both fields. Engineers are exploring alternative fuels such as hydrogen or biofuels for aviation while also investigating electric propulsion systems that could revolutionize air travel by reducing greenhouse gas emissions.

The push for greener technologies is not only driven by regulatory pressures but also by consumer demand for environmentally friendly solutions. However, challenges remain on the horizon for mechanical and aerospace engineers. The rapid pace of technological advancement necessitates continuous learning and adaptation within the workforce.

Engineers must stay abreast of emerging technologies such as artificial intelligence and machine learning that are becoming integral to design processes and operational efficiencies. Additionally, addressing cybersecurity concerns related to automated systems is paramount as reliance on digital technologies increases across both fields. In conclusion, mechanical and aerospace engineering stands at a crossroads where innovation meets necessity.

The integration of advanced materials, manufacturing techniques, propulsion systems, automation technologies, and sustainable practices will define the future landscape of these disciplines. As engineers tackle complex challenges ranging from climate change to space exploration, their contributions will undoubtedly shape the world we live in today and tomorrow.