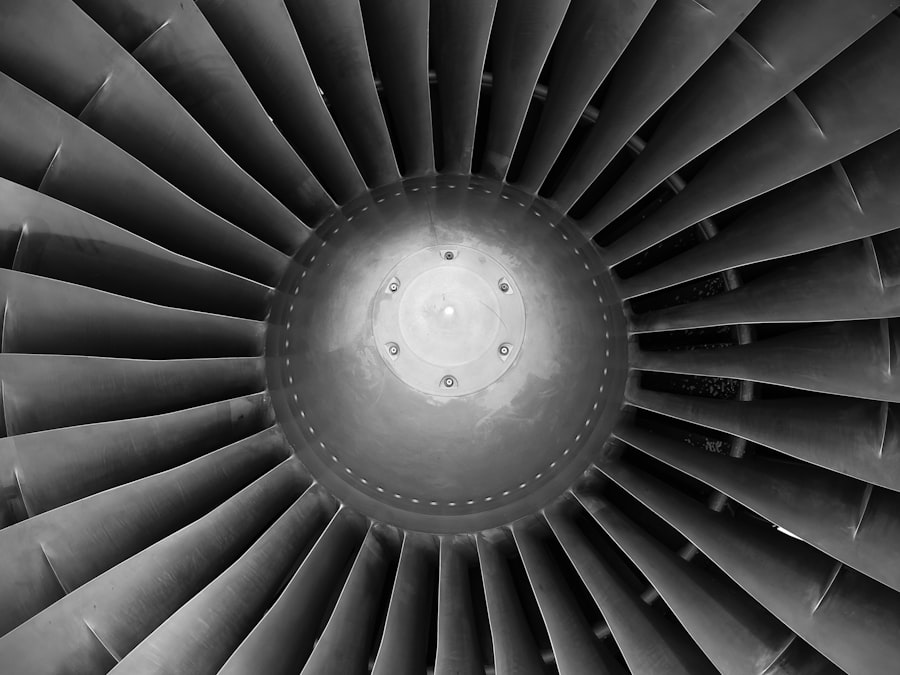

Military aerospace coatings play a crucial role in the performance, durability, and operational effectiveness of military aircraft and related equipment. These specialized coatings are designed to withstand extreme environmental conditions, including high temperatures, corrosive atmospheres, and mechanical wear. They serve multiple functions, such as providing camouflage, reducing radar signatures, and enhancing the overall aesthetic appeal of military assets.

The importance of these coatings cannot be overstated, as they directly impact the longevity and reliability of military aircraft, which are often subjected to rigorous operational demands. The development of military aerospace coatings is a complex interplay of materials science, engineering, and military requirements. These coatings must not only meet stringent performance criteria but also comply with various regulatory standards.

As military operations evolve and technology advances, the demand for innovative coating solutions continues to grow. This article delves into the historical context, current trends, key players, challenges, and future prospects of military aerospace coatings, providing a comprehensive overview of this vital sector.

Key Takeaways

- Military aerospace coatings play a crucial role in protecting aircraft from corrosion, weathering, and other environmental factors.

- The development of military aerospace coatings can be traced back to the early 20th century, with significant advancements during World War II.

- Current market trends in military aerospace coatings include the use of advanced materials, nanotechnology, and environmentally friendly coatings.

- Key players in the military aerospace coatings market include PPG Industries, AkzoNobel, Sherwin-Williams, and Hentzen Coatings, with a focus on innovations in durability and performance.

- Challenges in the military aerospace coatings market include strict regulatory requirements and the need for continuous innovation, while opportunities lie in the development of coatings for unmanned aerial vehicles and the growing demand for eco-friendly coatings.

Historical Overview of Military Aerospace Coatings

The history of military aerospace coatings can be traced back to the early days of aviation when rudimentary protective finishes were applied to aircraft to prevent corrosion and wear. During World War I, the need for more effective coatings became apparent as aircraft were exposed to harsh weather conditions and combat environments. Early coatings were primarily oil-based paints that offered limited protection but laid the groundwork for future advancements.

As technology progressed through World War II and into the Cold War era, the development of synthetic polymers revolutionized the field of aerospace coatings. These new materials provided enhanced durability and resistance to environmental factors. The introduction of epoxy and polyurethane coatings marked a significant milestone, offering improved adhesion and flexibility.

The military’s focus on stealth technology in the late 20th century further propelled innovations in coatings, leading to the development of radar-absorbing materials that minimized aircraft visibility to enemy radar systems. This historical evolution highlights the ongoing quest for improved performance and protection in military aerospace applications.

Current Market Trends and Technologies in Military Aerospace Coatings

Today, the military aerospace coatings market is characterized by rapid technological advancements and a growing emphasis on multifunctionality. One notable trend is the increasing adoption of nanotechnology in coating formulations. Nanoparticles are being incorporated into coatings to enhance properties such as scratch resistance, thermal stability, and anti-corrosion capabilities.

For instance, titanium dioxide nanoparticles are used to improve UV resistance and self-cleaning properties, which are particularly beneficial for aircraft operating in diverse environments. Another significant trend is the shift towards environmentally friendly coatings. With growing awareness of environmental issues and stricter regulations, manufacturers are developing low-VOC (volatile organic compound) and water-based coatings that minimize harmful emissions during application.

These eco-friendly alternatives not only comply with regulatory standards but also offer comparable performance to traditional solvent-based coatings. Additionally, advancements in application techniques, such as electrostatic spraying and advanced curing methods, are improving efficiency and reducing waste in the coating process.

Key Players and Innovations in Military Aerospace Coatings

| Key Players | Innovations |

|---|---|

| PPG Industries | Advanced corrosion-resistant coatings |

| AkzoNobel | Environmentally friendly coatings |

| Sherwin-Williams | High-performance aerospace coatings |

| Hentzen Coatings | Customized coating solutions |

The military aerospace coatings market is populated by several key players who are at the forefront of innovation. Companies like PPG Industries, AkzoNobel, and Sherwin-Williams have established themselves as leaders by investing heavily in research and development. PPG Industries, for example, has developed a range of advanced coatings that provide superior protection against corrosion and environmental degradation while also offering stealth capabilities through radar-absorbing technologies.

Innovations in this sector are not limited to established players; smaller companies and startups are also making significant contributions. For instance, companies specializing in nanotechnology are creating coatings that leverage the unique properties of nanomaterials to enhance performance characteristics. These innovations are often driven by collaboration between industry players and research institutions, fostering an environment where cutting-edge technologies can be rapidly developed and brought to market.

Challenges and Opportunities in the Military Aerospace Coatings Market

Despite the promising growth prospects in the military aerospace coatings market, several challenges persist. One major issue is the high cost associated with developing and implementing advanced coating technologies. Research and development require substantial investment, which can be a barrier for smaller companies looking to enter the market.

Additionally, the complexity of military specifications can complicate the approval process for new coatings, leading to delays in bringing innovative products to market. However, these challenges also present opportunities for growth. The increasing demand for lightweight materials in military applications is driving innovation in coating technologies that can enhance performance without adding significant weight.

Furthermore, as militaries around the world modernize their fleets and invest in next-generation aircraft, there is a growing need for advanced coatings that can meet evolving operational requirements. Companies that can navigate these challenges while delivering innovative solutions stand to gain a competitive advantage in this dynamic market.

Regulatory and Environmental Considerations in Military Aerospace Coatings

Regulatory compliance is a critical aspect of the military aerospace coatings industry. Various agencies, including the Environmental Protection Agency (EPA) in the United States and similar organizations worldwide, impose strict regulations on the use of hazardous materials in coating formulations. These regulations aim to protect both human health and the environment from harmful substances commonly found in traditional coatings.

In response to these regulatory pressures, manufacturers are increasingly focusing on developing sustainable coating solutions that meet environmental standards without compromising performance. The transition towards low-VOC and water-based formulations is a direct result of these regulatory considerations. Additionally, manufacturers are exploring alternative raw materials derived from renewable sources to create eco-friendly coatings that align with global sustainability goals.

Future Prospects and Growth Potential of Military Aerospace Coatings

The future of military aerospace coatings appears promising as technological advancements continue to reshape the landscape. The integration of smart coatings—those that can respond to environmental stimuli or provide real-time monitoring—represents a significant frontier for innovation. These smart coatings could offer enhanced functionality by incorporating sensors that detect damage or environmental changes, allowing for proactive maintenance strategies.

Moreover, as geopolitical tensions persist and defense budgets remain robust in many countries, investment in military capabilities is expected to rise. This trend will likely drive demand for advanced aerospace coatings that enhance aircraft performance and survivability. The ongoing development of unmanned aerial vehicles (UAVs) and next-generation fighter jets will further fuel innovation in this sector as manufacturers seek to create specialized coatings tailored to these advanced platforms.

Conclusion and Recommendations for the Military Aerospace Coatings Industry

The military aerospace coatings industry stands at a crossroads where innovation meets regulatory compliance and environmental responsibility. To thrive in this evolving landscape, companies must prioritize research and development while embracing sustainable practices. Collaborations between industry players and research institutions can accelerate innovation cycles and lead to breakthroughs in coating technologies.

Furthermore, staying attuned to market trends and customer needs will be essential for maintaining competitiveness. As militaries around the world continue to modernize their fleets, there will be ample opportunities for companies that can deliver high-performance coatings that meet stringent requirements while also addressing environmental concerns. By focusing on these areas, stakeholders in the military aerospace coatings industry can position themselves for success in an increasingly complex market environment.