Aerospace additive manufacturing, often referred to as 3D printing, represents a transformative approach to the design and production of components within the aerospace sector. This technology allows for the layer-by-layer construction of parts, utilizing materials such as metals, polymers, and composites. Unlike traditional manufacturing methods, which often involve subtractive processes that can waste significant amounts of material, additive manufacturing builds objects from the ground up, enabling the creation of complex geometries that were previously impossible or prohibitively expensive to produce.

The implications of this technology extend far beyond mere cost savings; they encompass enhanced design flexibility, reduced lead times, and the potential for on-demand production. The aerospace industry, characterized by its stringent requirements for safety, performance, and reliability, has been particularly receptive to the innovations brought forth by additive manufacturing. The ability to produce lightweight components with intricate designs can lead to significant improvements in fuel efficiency and overall aircraft performance.

Moreover, as the industry grapples with increasing demand for more efficient and sustainable practices, additive manufacturing offers a pathway to reduce waste and energy consumption throughout the production process. As we delve deeper into this subject, it becomes evident that aerospace additive manufacturing is not merely a trend but a fundamental shift in how aerospace components are conceived, designed, and manufactured.

Key Takeaways

- Aerospace additive manufacturing is revolutionizing the aerospace industry by using 3D printing technology to create complex and lightweight parts.

- The aerospace additive manufacturing market is experiencing rapid growth and has the potential to transform the industry by reducing lead times and costs.

- Key players in aerospace additive manufacturing include companies like Boeing, Airbus, and GE Aviation, who are driving innovation in materials and processes.

- Challenges in aerospace additive manufacturing include quality control and certification, but opportunities exist in creating customized parts and reducing waste.

- Aerospace additive manufacturing is impacting supply chains and production by enabling on-demand manufacturing and reducing the need for large inventories.

The Growth and Potential of the Aerospace Additive Manufacturing Market

The aerospace additive manufacturing market has experienced remarkable growth over the past decade, driven by advancements in technology and an increasing recognition of its benefits. According to industry reports, the market is projected to reach several billion dollars in value within the next few years, reflecting a compound annual growth rate (CAGR) that underscores its burgeoning significance. This growth is fueled by a variety of factors, including the rising demand for lightweight components that enhance fuel efficiency and reduce emissions.

As airlines and manufacturers strive to meet stringent environmental regulations, the ability to produce parts that are both lighter and stronger becomes increasingly critical. Furthermore, the potential applications of additive manufacturing in aerospace are vast. From prototyping to end-use parts, the technology can be employed at various stages of production.

For instance, companies like Boeing and Airbus have begun integrating 3D-printed components into their aircraft designs, utilizing additive manufacturing for everything from engine parts to cabin interiors. The ability to rapidly iterate designs and produce customized components on demand not only accelerates the development cycle but also allows for greater innovation in aircraft design. As the technology matures and becomes more widely adopted, it is expected that new applications will emerge, further expanding the market’s potential.

Key Players and Innovations in Aerospace Additive Manufacturing

The landscape of aerospace additive manufacturing is populated by a diverse array of key players, each contributing unique innovations that drive the industry forward. Major aerospace manufacturers such as Boeing and Airbus have invested heavily in additive manufacturing technologies, establishing partnerships with specialized firms like Stratasys and GE Additive. These collaborations have led to significant advancements in material science and printing techniques, enabling the production of high-performance components that meet rigorous aerospace standards.

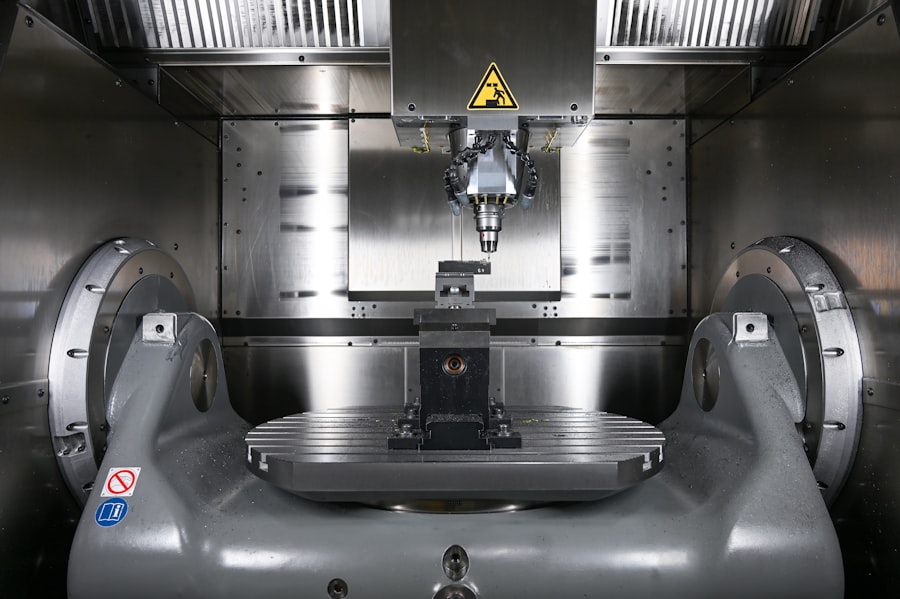

One notable innovation is the development of metal additive manufacturing processes such as Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM). These techniques allow for the creation of complex metal parts with exceptional mechanical properties. For example, GE Aviation has successfully utilized DMLS to produce fuel nozzles for its LEAP engines, resulting in a part that is 25% lighter than its traditionally manufactured counterpart while also improving performance.

Such innovations not only enhance product performance but also streamline production processes, reducing lead times and costs associated with traditional manufacturing methods.

Challenges and Opportunities in Aerospace Additive Manufacturing

| Challenges | Opportunities |

|---|---|

| Complex geometries | Design freedom |

| Material properties | Lightweight components |

| Quality control | Customization |

| Cost of equipment | Supply chain efficiency |

Despite its many advantages, aerospace additive manufacturing faces several challenges that must be addressed for widespread adoption. One significant hurdle is the certification process for 3D-printed parts. The aerospace industry is governed by strict regulatory standards that ensure safety and reliability; thus, obtaining certification for new manufacturing processes can be a lengthy and complex endeavor.

Each new material or design must undergo rigorous testing to demonstrate compliance with safety regulations, which can slow down the integration of additive manufacturing into mainstream production. However, these challenges also present opportunities for innovation. As companies work to navigate the certification landscape, there is a growing need for standardized testing protocols and guidelines specific to additive manufacturing.

Organizations such as ASTM International are actively developing standards that will facilitate the certification process for 3D-printed aerospace components. Additionally, advancements in simulation software and digital twin technologies are enabling manufacturers to predict performance outcomes more accurately, thereby expediting the certification process. By addressing these challenges head-on, the industry can unlock the full potential of additive manufacturing.

The Impact of Aerospace Additive Manufacturing on Supply Chains and Production

Aerospace additive manufacturing has the potential to revolutionize supply chains by enabling more localized production and reducing dependency on traditional supply networks. The ability to produce parts on demand means that manufacturers can maintain lower inventory levels while still meeting customer needs efficiently. This shift not only reduces storage costs but also minimizes waste associated with overproduction—a significant concern in traditional manufacturing paradigms.

Moreover, additive manufacturing can enhance supply chain resilience by allowing for rapid response to disruptions. For instance, during the COVID-19 pandemic, many manufacturers faced significant delays due to global supply chain interruptions. Companies that had already adopted additive manufacturing were able to pivot quickly, producing critical components in-house rather than relying on external suppliers.

This adaptability highlights how 3D printing can serve as a strategic asset in times of uncertainty, allowing aerospace companies to maintain operational continuity while navigating challenges.

Regulatory and Safety Considerations in Aerospace Additive Manufacturing

The regulatory landscape surrounding aerospace additive manufacturing is complex and multifaceted. Given the critical nature of safety in aviation, regulatory bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established stringent guidelines governing the use of 3D-printed components in aircraft. These regulations are designed to ensure that all parts meet rigorous safety standards before they can be used in commercial applications.

One of the primary concerns is ensuring that 3D-printed parts possess mechanical properties equivalent to those produced through traditional methods. This necessitates extensive testing and validation processes to demonstrate that these components can withstand the stresses encountered during flight operations. Additionally, manufacturers must maintain comprehensive documentation throughout the production process to trace each part’s origin and ensure compliance with regulatory requirements.

As the industry continues to evolve, ongoing collaboration between manufacturers and regulatory bodies will be essential in developing frameworks that support innovation while prioritizing safety.

Future Trends and Developments in Aerospace Additive Manufacturing

Looking ahead, several trends are poised to shape the future of aerospace additive manufacturing. One significant development is the increasing integration of artificial intelligence (AI) and machine learning into the design and production processes. These technologies can optimize designs for additive manufacturing by analyzing performance data and identifying areas for improvement.

For instance, AI algorithms can suggest modifications that enhance structural integrity while minimizing weight—an essential consideration in aerospace applications. Another trend is the exploration of new materials specifically tailored for additive manufacturing in aerospace contexts. Researchers are investigating advanced alloys and composites that offer superior performance characteristics while being compatible with 3D printing technologies.

The development of these materials could expand the range of applications for additive manufacturing within aerospace, enabling even more innovative designs and improved performance metrics.

The Future of Aerospace Additive Manufacturing

As we look toward the future of aerospace additive manufacturing, it is clear that this technology will play an increasingly pivotal role in shaping the industry landscape. With its ability to streamline production processes, reduce waste, and enable innovative designs, additive manufacturing offers a compelling solution to many of the challenges faced by aerospace manufacturers today. While hurdles remain—particularly concerning regulatory compliance and material certification—the ongoing advancements in technology and collaborative efforts among industry stakeholders are paving the way for broader adoption.

The future promises not only enhanced efficiency but also a reimagining of what is possible within aerospace design and production. As companies continue to explore new applications and refine their processes, we can expect to see a wave of innovation that will redefine how aircraft are built and operated. In this dynamic environment, those who embrace additive manufacturing will likely find themselves at the forefront of a new era in aerospace engineering—one characterized by agility, sustainability, and unprecedented creativity.