The aerospace forging market is a critical segment of the broader aerospace industry, which encompasses the design, manufacture, and maintenance of aircraft and spacecraft. Forging, a manufacturing process that involves shaping metal using localized compressive forces, is essential for producing high-strength components that can withstand the extreme conditions encountered in aviation and space travel. The aerospace sector demands materials that not only exhibit superior mechanical properties but also meet stringent safety and performance standards.

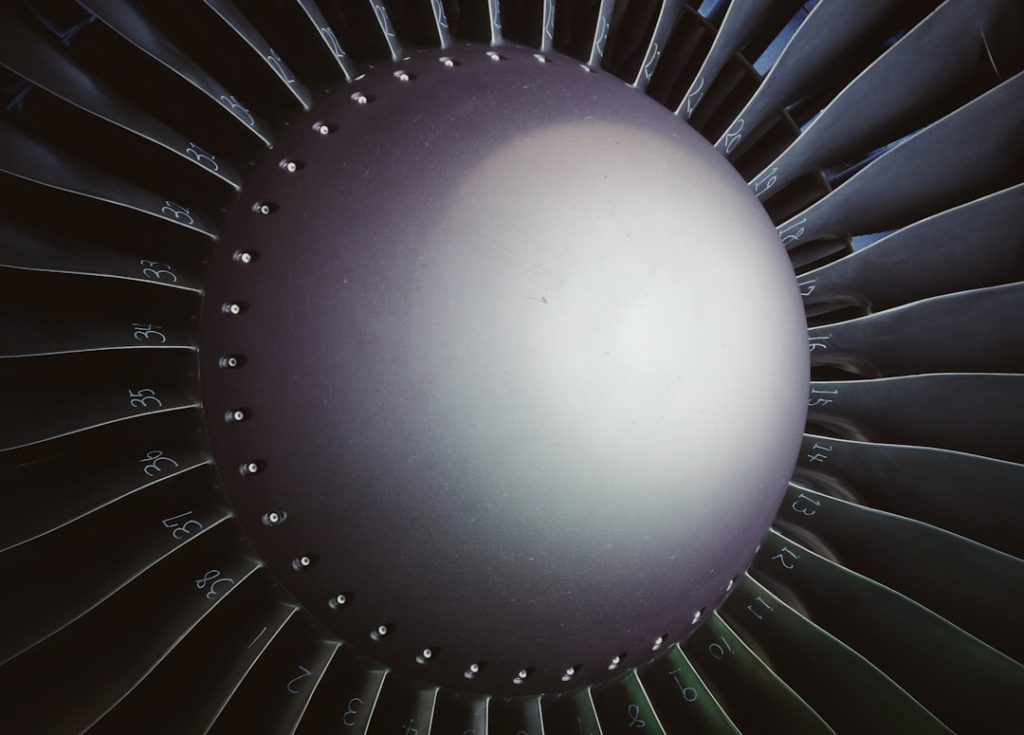

As a result, the forging process is employed to create components such as landing gear, engine parts, and structural elements that are integral to the performance and safety of aircraft. The aerospace forging market has witnessed significant growth over the past few years, driven by an increase in air travel demand, advancements in technology, and a growing focus on lightweight materials. The global aerospace industry is projected to expand further, fueled by rising passenger numbers and the need for more fuel-efficient aircraft.

This growth has led to an increased demand for forged components that can enhance the performance and durability of aircraft. As manufacturers strive to meet these demands, the aerospace forging market is evolving, with innovations in materials and processes that promise to redefine the landscape of aerospace manufacturing.

Key Takeaways

- Aerospace forging market is a crucial part of the aerospace industry, involving the shaping of metal components for aircraft and spacecraft.

- Factors driving growth in aerospace forging market include increasing demand for lightweight and high-strength materials, growth in air travel, and rising defense budgets.

- Key players in aerospace forging industry include Precision Castparts Corp., Arconic, and Bharat Forge, with trends such as increasing use of advanced materials and additive manufacturing.

- Technological advancements in aerospace forging include the use of 3D printing, advanced simulation software, and automation for improved efficiency and precision.

- Market opportunities in aerospace forging include the growing demand for commercial aircraft, while challenges include stringent regulations and environmental impact.

Factors Driving the Growth in Aerospace Forging Market

Several factors are propelling the growth of the aerospace forging market. One of the primary drivers is the increasing demand for air travel, which has surged in recent years due to globalization and rising disposable incomes. According to the International Air Transport Association (IATA), global passenger traffic is expected to double over the next two decades, necessitating the production of more aircraft.

This surge in demand translates into a greater need for high-quality forged components that can ensure the safety and reliability of new aircraft models. Another significant factor contributing to market growth is the ongoing technological advancements in aerospace manufacturing processes. Innovations such as computer numerical control (CNC) machining and additive manufacturing are being integrated with traditional forging techniques to enhance precision and efficiency.

These advancements allow manufacturers to produce complex geometries and lightweight components that were previously unattainable. Additionally, the aerospace industry’s shift towards using advanced materials, such as titanium and high-strength aluminum alloys, further drives the demand for specialized forging processes capable of handling these materials.

Key Players and Market Trends in Aerospace Forging Industry

The aerospace forging industry is characterized by a mix of established players and emerging companies that are vying for market share. Major companies such as Alcoa Corporation, Precision Castparts Corp., and Rolls-Royce Holdings plc dominate the landscape, leveraging their extensive experience and technological capabilities to deliver high-quality forged components. These companies invest heavily in research and development to stay ahead of industry trends and meet evolving customer demands.

Market trends indicate a growing emphasis on sustainability within the aerospace forging sector. As environmental concerns become increasingly prominent, manufacturers are exploring ways to reduce waste and energy consumption during the forging process. This includes adopting more efficient production techniques and utilizing recycled materials whenever possible.

Furthermore, there is a noticeable shift towards collaborative partnerships between aerospace manufacturers and forging companies, aimed at fostering innovation and improving supply chain efficiency. Such collaborations enable companies to share knowledge and resources, ultimately leading to enhanced product offerings and reduced lead times.

Technological Advancements in Aerospace Forging

| Technological Advancements | Benefits |

|---|---|

| Advanced Materials | Improved strength-to-weight ratio |

| Computer-Aided Design (CAD) | Enhanced precision and efficiency |

| 3D Printing | Complex part production and customization |

| Robotics and Automation | Increased productivity and safety |

| Non-Destructive Testing (NDT) | Enhanced quality control and inspection |

Technological advancements play a pivotal role in shaping the aerospace forging market. One notable innovation is the development of advanced forging techniques such as isothermal forging and warm forging. Isothermal forging involves maintaining a constant temperature throughout the forging process, which enhances material properties and reduces internal stresses.

This technique is particularly beneficial for producing complex shapes with high strength-to-weight ratios, making it ideal for aerospace applications. Additionally, the integration of digital technologies into the forging process has revolutionized how manufacturers operate. The use of simulation software allows engineers to model and analyze forging processes before actual production begins, minimizing errors and optimizing designs.

Moreover, Industry 4.0 concepts are being adopted within the aerospace forging sector, enabling real-time monitoring of production processes through IoT devices. This connectivity facilitates predictive maintenance, reduces downtime, and enhances overall operational efficiency.

Market Opportunities and Challenges in Aerospace Forging

The aerospace forging market presents numerous opportunities for growth, particularly as new aircraft models are developed to meet changing consumer preferences and regulatory requirements. The increasing focus on fuel efficiency has led manufacturers to seek lighter materials that can improve aircraft performance while reducing emissions. This trend opens up avenues for innovative forging solutions that cater to these needs.

However, challenges persist within the aerospace forging industry. One significant hurdle is the volatility of raw material prices, particularly for metals like titanium and aluminum, which are essential for aerospace applications. Fluctuations in material costs can impact profit margins and complicate long-term planning for manufacturers.

Additionally, maintaining compliance with stringent regulatory standards poses another challenge. The aerospace industry is subject to rigorous safety regulations that require manufacturers to adhere to strict quality control measures throughout the production process.

Global Market Analysis and Forecast for Aerospace Forging

The global aerospace forging market is poised for substantial growth over the coming years. According to industry reports, the market is expected to expand at a compound annual growth rate (CAGR) of approximately 5% from 2023 to 2030. North America currently holds a significant share of the market due to its established aerospace manufacturing base and presence of major players in the region.

The United States, in particular, remains a leader in aircraft production, driving demand for forged components. Emerging markets in Asia-Pacific are also anticipated to contribute significantly to market growth. Countries like China and India are investing heavily in their aerospace sectors, driven by increasing air travel demand and government initiatives aimed at boosting domestic manufacturing capabilities.

As these markets continue to develop, they present lucrative opportunities for both established players and new entrants in the aerospace forging industry.

Environmental and Regulatory Impact on Aerospace Forging Market

The environmental impact of manufacturing processes has become a focal point for industries worldwide, including aerospace forging. Manufacturers are increasingly adopting sustainable practices aimed at minimizing their carbon footprint and reducing waste generation. This includes implementing energy-efficient technologies in their operations and exploring alternative materials that have less environmental impact.

Regulatory frameworks also play a crucial role in shaping the aerospace forging market. Governments around the world have established stringent regulations governing emissions, waste management, and material sourcing within the aerospace sector. Compliance with these regulations is essential for manufacturers seeking to maintain their competitive edge while ensuring product safety and environmental responsibility.

As regulatory pressures continue to evolve, companies must remain agile in adapting their practices to meet these requirements while still delivering high-quality forged components.

Conclusion and Future Outlook for Aerospace Forging Industry

The future outlook for the aerospace forging industry appears promising as it adapts to meet the demands of an evolving market landscape. With increasing air travel demand, technological advancements, and a focus on sustainability driving growth, manufacturers are well-positioned to capitalize on emerging opportunities. The integration of innovative forging techniques and digital technologies will likely enhance production efficiency while improving product quality.

As challenges such as raw material volatility and regulatory compliance persist, companies must remain proactive in addressing these issues through strategic planning and investment in research and development. The collaboration between aerospace manufacturers and forging companies will be crucial in fostering innovation and ensuring that the industry continues to thrive in an increasingly competitive environment. Overall, the aerospace forging market is set to play a vital role in shaping the future of aviation and space exploration as it evolves alongside technological advancements and changing consumer expectations.