Aerospace Manufacturing Co. stands at the forefront of the aerospace industry, a sector characterized by its complexity and the high stakes involved in producing components for aircraft and spacecraft. Established with a vision to innovate and excel, the company has carved a niche for itself by focusing on precision engineering and cutting-edge technology.

The aerospace sector demands not only rigorous adherence to safety standards but also a commitment to quality and efficiency, which Aerospace Manufacturing Co. has consistently delivered. With a diverse portfolio that includes everything from commercial aircraft parts to advanced satellite components, the company plays a pivotal role in the global aerospace supply chain.

The company’s commitment to excellence is reflected in its state-of-the-art facilities, which are equipped with the latest manufacturing technologies. These facilities are designed to accommodate a wide range of production processes, from traditional machining to advanced composite fabrication. The workforce at Aerospace Manufacturing Co.

is highly skilled, comprising engineers, technicians, and specialists who are dedicated to pushing the boundaries of what is possible in aerospace manufacturing. This blend of human expertise and technological prowess positions the company as a leader in an industry that is constantly evolving.

Key Takeaways

- Aerospace Manufacturing Co. is a leading company in the aerospace industry, specializing in the production of aircraft and spacecraft components.

- Advancements in materials and technology have revolutionized aerospace manufacturing, leading to the development of lighter, stronger, and more durable materials for aircraft and spacecraft construction.

- Automation and robotics play a crucial role in aerospace manufacturing, improving efficiency, precision, and safety in the production process.

- Sustainable practices, such as recycling and waste reduction, are becoming increasingly important in aerospace manufacturing to minimize environmental impact.

- Additive manufacturing, also known as 3D printing, is transforming aerospace manufacturing by enabling the production of complex and lightweight components with reduced material waste.

The aerospace industry has witnessed remarkable advancements in materials science, which have significantly enhanced the performance and efficiency of aircraft and spacecraft. Aerospace Manufacturing Co. has been at the forefront of these developments, investing heavily in research and development to explore new materials that can withstand extreme conditions while being lightweight.

For instance, the use of carbon fiber reinforced polymers (CFRP) has revolutionized aircraft design, allowing for structures that are both strong and lightweight. This shift not only improves fuel efficiency but also enhances overall performance. In addition to CFRP, Aerospace Manufacturing Co.

has explored the potential of advanced alloys and composites that offer superior strength-to-weight ratios. Titanium alloys, for example, are increasingly used in critical components due to their excellent corrosion resistance and high strength. The company has also embraced nanotechnology, which enables the creation of materials with enhanced properties at the molecular level.

These innovations are not merely theoretical; they have been successfully integrated into various projects, resulting in tangible improvements in aircraft performance and safety.

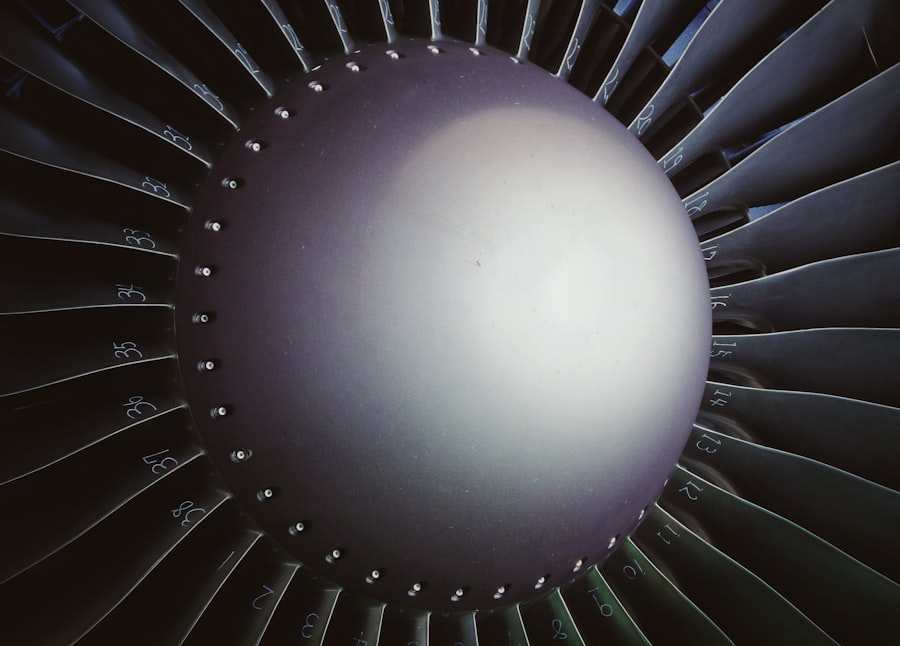

Automation and Robotics in Aerospace Manufacturing

Automation and robotics have become integral to modern aerospace manufacturing, driving efficiency and precision in production processes. Aerospace Manufacturing Co. has adopted advanced robotic systems that streamline operations, reduce human error, and enhance productivity.

For example, robotic arms are employed for tasks such as drilling, riveting, and assembly, where precision is paramount. These systems can operate continuously with minimal downtime, significantly increasing output while maintaining high-quality standards. Moreover, the integration of automation extends beyond just physical tasks; it encompasses data collection and analysis as well.

Automated systems can monitor production metrics in real-time, allowing for immediate adjustments to be made if deviations from quality standards occur. This level of responsiveness is crucial in an industry where even minor defects can have catastrophic consequences. By leveraging robotics and automation, Aerospace Manufacturing Co.

not only improves its operational efficiency but also ensures that it meets the stringent regulatory requirements that govern aerospace manufacturing.

Sustainable Practices in Aerospace Manufacturing

As environmental concerns continue to rise globally, Aerospace Manufacturing Co. recognizes the importance of adopting sustainable practices within its operations. The company has implemented various initiatives aimed at reducing its carbon footprint and minimizing waste throughout the manufacturing process.

One significant area of focus is energy efficiency; by upgrading machinery and optimizing production schedules, the company has achieved substantial reductions in energy consumption. Additionally, Aerospace Manufacturing Co. is committed to responsible sourcing of materials.

This involves selecting suppliers who adhere to sustainable practices and ensuring that raw materials are obtained from environmentally friendly sources. The company also actively participates in recycling programs, repurposing scrap materials generated during production rather than sending them to landfills. These efforts not only contribute to environmental sustainability but also resonate with customers who increasingly prioritize eco-friendly practices when selecting suppliers.

Additive Manufacturing in Aerospace

| Metrics | 2018 | 2019 | 2020 |

|---|---|---|---|

| Number of 3D printed aerospace components | 1,200 | 1,800 | 2,500 |

| Percentage of cost savings from additive manufacturing | 15% | 20% | 25% |

| Number of aerospace companies using additive manufacturing | 50 | 75 | 100 |

Additive manufacturing, commonly known as 3D printing, has emerged as a transformative technology in aerospace manufacturing. Aerospace Manufacturing Co. has embraced this innovation to produce complex components that were previously difficult or impossible to manufacture using traditional methods.

The ability to create intricate geometries with minimal material waste is particularly advantageous in an industry where weight reduction is critical for performance. One notable application of additive manufacturing within Aerospace Manufacturing Co. is the production of lightweight brackets and fixtures used in aircraft assembly.

By utilizing 3D printing techniques, the company can rapidly prototype designs and iterate on them without incurring significant costs or delays associated with traditional tooling methods. Furthermore, additive manufacturing allows for on-demand production, reducing inventory costs and lead times for critical components.

Digitalization and Data Analytics in Aerospace Manufacturing

The digital transformation of aerospace manufacturing is reshaping how companies operate and make decisions. Aerospace Manufacturing Co. has invested in digitalization initiatives that leverage data analytics to enhance operational efficiency and product quality.

By implementing Internet of Things (IoT) technologies, the company can collect vast amounts of data from machinery and production processes, providing insights into performance metrics that were previously difficult to obtain. Data analytics plays a crucial role in predictive maintenance strategies employed by Aerospace Manufacturing Co. By analyzing data trends from equipment sensors, the company can anticipate potential failures before they occur, minimizing downtime and maintenance costs.

This proactive approach not only enhances operational efficiency but also extends the lifespan of critical machinery. Additionally, data-driven decision-making enables the company to optimize production schedules and resource allocation, further improving overall productivity.

Collaborations and Partnerships in Aerospace Manufacturing

In an industry as complex as aerospace manufacturing, collaboration is essential for driving innovation and achieving common goals. Aerospace Manufacturing Co. actively seeks partnerships with other industry players, research institutions, and technology providers to foster knowledge sharing and accelerate advancements in manufacturing processes.

These collaborations often lead to joint research projects aimed at developing new technologies or improving existing ones. For instance, Aerospace Manufacturing Co. has partnered with universities to explore cutting-edge research in materials science and engineering.

Such collaborations not only provide access to emerging technologies but also help cultivate a skilled workforce through internships and training programs for students. Additionally, partnerships with other manufacturers enable the sharing of best practices and resources, ultimately benefiting all parties involved by enhancing competitiveness within the industry.

Looking ahead, Aerospace Manufacturing Co. is poised for continued growth and innovation within the aerospace sector. As global demand for air travel increases alongside advancements in space exploration, the company is strategically positioned to capitalize on emerging opportunities.

The ongoing development of electric and hybrid aircraft presents a new frontier for aerospace manufacturing, requiring innovative solutions that align with sustainability goals. Furthermore, as geopolitical dynamics shift and supply chains become more complex, Aerospace Manufacturing Co. is committed to enhancing its resilience through diversification of suppliers and investment in local manufacturing capabilities.

This approach not only mitigates risks associated with global supply chain disruptions but also aligns with a growing trend toward localized production. In summary, Aerospace Manufacturing Co.’s commitment to innovation, sustainability, and collaboration positions it as a leader in the aerospace manufacturing landscape. By embracing advancements in technology and materials while fostering partnerships across the industry, the company is well-equipped to navigate future challenges and seize new opportunities as they arise.