Aerodynamic engineering is a specialized field that focuses on the behavior of air as it interacts with solid objects, particularly vehicles. This discipline is crucial in various industries, including automotive, aerospace, and even civil engineering, where understanding airflow can significantly influence design and performance. The principles of aerodynamics are rooted in fluid dynamics, a branch of physics that studies the movement of fluids and the forces acting on them.

By applying these principles, engineers can optimize vehicle shapes to reduce drag, enhance stability, and improve fuel efficiency. The significance of aerodynamic engineering has grown exponentially with the increasing demand for high-performance vehicles that are also environmentally friendly. As global concerns about climate change and fuel consumption intensify, manufacturers are compelled to innovate and create designs that minimize air resistance while maximizing speed and efficiency.

This intersection of environmental responsibility and engineering excellence makes aerodynamic engineering a pivotal area of study and application in modern vehicle design.

Key Takeaways

- Aerodynamic engineering is the study of how air flows around objects and the forces that the air and objects exert on each other.

- Aerodynamics plays a crucial role in vehicle design, affecting performance, fuel efficiency, and stability.

- Aerodynamic engineers are responsible for designing and testing vehicle shapes to minimize drag and maximize performance.

- Key responsibilities of an aerodynamic engineer include conducting wind tunnel tests, using computational fluid dynamics, and optimizing vehicle shapes.

- Aerodynamic engineers face challenges such as balancing aerodynamics with other design considerations and meeting strict regulatory requirements.

The Importance of Aerodynamics in Vehicle Design

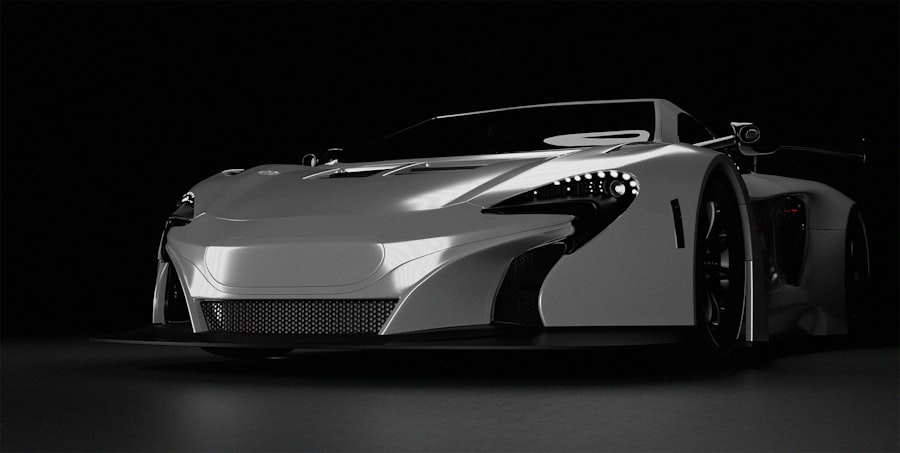

Aerodynamics plays a critical role in vehicle design, influencing not only performance but also safety and comfort. The shape of a vehicle directly affects how air flows around it, which in turn impacts drag force—the resistance encountered as the vehicle moves through the air. A well-designed vehicle can significantly reduce drag, leading to improved fuel efficiency and higher speeds.

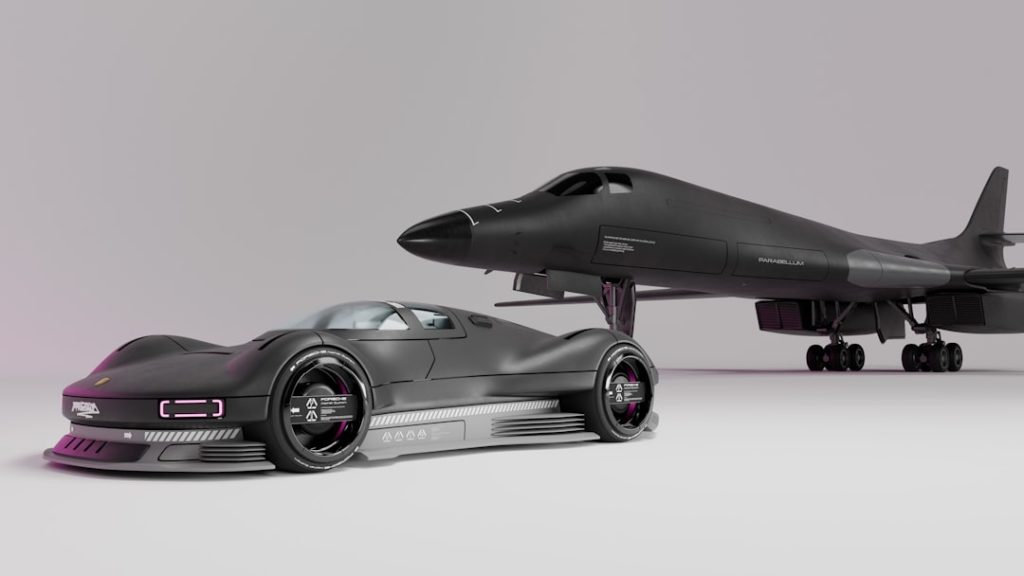

For instance, sports cars often feature sleek, low profiles that allow them to slice through the air more effectively than traditional vehicles, showcasing how aerodynamics can enhance performance. Moreover, aerodynamics is not solely about speed; it also contributes to stability and handling. Vehicles that are designed with aerodynamic principles in mind tend to have better road grip and control at high speeds.

This is particularly important for racing cars, where even minor improvements in aerodynamics can lead to substantial gains in lap times. Additionally, aerodynamics affects passenger comfort; for example, a vehicle with poor aerodynamic design may experience increased wind noise and turbulence inside the cabin, detracting from the overall driving experience.

The Role of an Aerodynamic Engineer in Vehicle Design

An aerodynamic engineer is a specialized professional who applies principles of fluid dynamics to the design and optimization of vehicles. Their primary goal is to enhance vehicle performance by minimizing drag and maximizing lift when necessary. This role requires a deep understanding of both theoretical concepts and practical applications, as engineers must translate complex aerodynamic theories into tangible design features.

They often collaborate with other engineers, designers, and manufacturers to ensure that aerodynamic considerations are integrated throughout the vehicle development process. In addition to improving performance metrics, aerodynamic engineers also focus on safety aspects related to airflow. For example, they analyze how air interacts with various components of a vehicle, such as spoilers, mirrors, and undercarriages, to identify potential issues that could affect stability or lead to dangerous situations at high speeds.

Their expertise is essential not only during the initial design phase but also throughout the testing and refinement stages, where they assess real-world performance against theoretical predictions.

Key Responsibilities of an Aerodynamic Engineer

| Key Responsibilities of an Aerodynamic Engineer |

|---|

| Designing and analyzing aerodynamic components |

| Conducting wind tunnel tests and simulations |

| Optimizing vehicle performance through aerodynamics |

| Collaborating with other engineering teams |

| Developing and implementing aerodynamic solutions |

| Researching and staying updated on aerodynamic advancements |

The responsibilities of an aerodynamic engineer are multifaceted and encompass various stages of vehicle development. One of their primary tasks is conducting computational fluid dynamics (CFD) simulations to predict how air will flow around a vehicle’s surface. These simulations allow engineers to visualize airflow patterns and identify areas where drag can be reduced or lift can be optimized.

By iterating on these designs through simulations, engineers can refine their models before physical prototypes are built. In addition to simulations, aerodynamic engineers are also involved in wind tunnel testing. This hands-on approach allows them to validate their CFD results by observing how scaled models perform in controlled environments.

Wind tunnel tests provide critical data on drag coefficients and lift forces, enabling engineers to make informed decisions about design modifications. Furthermore, they must document their findings meticulously and communicate results effectively to stakeholders, ensuring that all team members understand the implications of aerodynamic considerations on overall vehicle performance.

Tools and Techniques Used by Aerodynamic Engineers

Aerodynamic engineers utilize a variety of tools and techniques to analyze and optimize vehicle designs. One of the most significant tools at their disposal is computational fluid dynamics (CFD) software. Programs like ANSYS Fluent or OpenFOAM allow engineers to create detailed simulations of airflow around complex geometries.

These simulations can model various conditions, such as different speeds or environmental factors like wind direction and temperature, providing insights that are crucial for effective design. In addition to CFD software, wind tunnels remain an essential tool for aerodynamic testing. Engineers use both subsonic and supersonic wind tunnels to evaluate how vehicles perform under different airflow conditions.

These facilities enable engineers to test scale models or full-sized prototypes in a controlled environment, allowing for precise measurements of drag forces and other aerodynamic characteristics. Furthermore, advancements in technology have led to the integration of particle image velocimetry (PIV) systems within wind tunnels, which provide detailed visualizations of airflow patterns around test subjects.

Challenges Faced by Aerodynamic Engineers in Vehicle Design

Aerodynamic engineers encounter numerous challenges throughout the vehicle design process. One significant challenge is balancing aesthetics with functionality; while a sleek design may enhance aerodynamics, it must also appeal to consumers’ tastes and preferences. Striking this balance requires innovative thinking and collaboration with designers who may prioritize visual appeal over aerodynamic efficiency.

Another challenge lies in the ever-evolving regulatory landscape surrounding emissions and fuel efficiency standards. As governments implement stricter regulations aimed at reducing carbon footprints, aerodynamic engineers must continuously adapt their designs to meet these requirements without compromising performance or safety. This often involves extensive research and development efforts to explore new materials or technologies that can enhance aerodynamic performance while adhering to regulatory constraints.

Impact of Aerodynamic Design on Vehicle Efficiency

The impact of aerodynamic design on vehicle efficiency cannot be overstated. A well-optimized vehicle can achieve significant improvements in fuel economy by reducing drag forces that oppose motion. For example, studies have shown that even small reductions in drag coefficient can lead to substantial fuel savings over time; a reduction of just 0.01 in drag coefficient can result in approximately 1% improvement in fuel efficiency at highway speeds.

Moreover, aerodynamic design influences electric vehicles (EVs) as well. With the growing popularity of EVs, manufacturers are increasingly focusing on aerodynamics to extend range—an essential factor for consumer acceptance. For instance, Tesla’s Model S features a remarkably low drag coefficient of 0.24, which contributes significantly to its impressive range compared to other electric vehicles on the market.

This demonstrates how effective aerodynamic design can enhance not only traditional combustion engine vehicles but also the emerging electric vehicle segment.

Future Trends in Aerodynamic Engineering for Vehicle Design

As technology continues to advance, several trends are emerging in aerodynamic engineering that promise to reshape vehicle design in the coming years. One notable trend is the increasing use of artificial intelligence (AI) and machine learning algorithms in aerodynamic simulations. These technologies can analyze vast amounts of data from previous designs and simulations to identify optimal shapes more quickly than traditional methods allow.

This could lead to faster iterations in design processes and more innovative solutions for reducing drag. Another trend is the integration of biomimicry into aerodynamic design practices. Engineers are increasingly looking to nature for inspiration when developing new shapes that minimize drag or enhance stability.

For example, studying the streamlined bodies of fish or birds has led to innovative designs that mimic these natural forms, resulting in vehicles that perform better under various conditions. Additionally, sustainability is becoming a central theme in aerodynamic engineering as manufacturers seek eco-friendly materials and processes that align with global sustainability goals. The use of lightweight materials not only improves aerodynamics but also reduces energy consumption during production and operation.

As the automotive industry continues its shift toward greener practices, aerodynamic engineers will play a crucial role in developing designs that meet both performance standards and environmental responsibilities. In conclusion, aerodynamic engineering is an essential discipline that significantly influences vehicle design across various sectors. As technology evolves and societal demands shift toward sustainability and efficiency, the role of aerodynamic engineers will become increasingly vital in shaping the future of transportation.