Aeronautical design is a multifaceted discipline that encompasses the conception, development, and refinement of aircraft and spacecraft. It is a field that combines principles from various engineering domains, including mechanical, electrical, and materials engineering, to create vehicles capable of flight. The design process involves a thorough understanding of aerodynamics, propulsion systems, structural integrity, and human factors, all of which must be harmonized to produce safe and efficient flying machines.

The complexity of aeronautical design is underscored by the rigorous regulatory frameworks that govern aviation safety and performance, necessitating a meticulous approach to every aspect of the design process. The significance of aeronautical design extends beyond mere functionality; it plays a crucial role in shaping the future of transportation, defense, and exploration. As global demand for air travel continues to rise, the need for innovative designs that enhance efficiency and reduce environmental impact becomes increasingly pressing.

The interplay between creativity and technical knowledge in aeronautical design not only drives advancements in aircraft capabilities but also influences the broader aerospace industry, including satellite technology and space exploration initiatives. This dynamic field is characterized by continuous evolution, driven by technological advancements and changing societal needs.

Key Takeaways

- Aeronautical design has evolved significantly, integrating advanced materials and manufacturing techniques.

- Improvements in aerodynamics have led to enhanced aircraft performance and efficiency.

- Modern aircraft design increasingly incorporates cutting-edge technology for better functionality.

- Sustainability and environmental impact are now key considerations in engineering decisions.

- Future trends focus on safety, ergonomics, and innovative solutions for next-generation aircraft.

Evolution of Aircraft Engineering

The history of aircraft engineering is a testament to human ingenuity and the relentless pursuit of flight. From the early days of aviation, marked by the Wright brothers’ first powered flight in 1903, to the sophisticated jetliners and military aircraft of today, the evolution of aircraft engineering has been shaped by a series of groundbreaking innovations. The initial focus was on achieving basic flight capabilities, which led to the development of biplanes and monoplanes.

These early designs were rudimentary, relying on simple structures and limited power sources. However, as engineers gained insights into aerodynamics and propulsion, aircraft began to evolve rapidly. The introduction of metal structures during World War I marked a significant turning point in aircraft engineering.

The transition from wood and fabric to all-metal designs allowed for greater strength and durability, enabling faster and more powerful aircraft. The interwar period saw further advancements with the advent of retractable landing gear and more efficient engines. By World War II, aircraft engineering had reached new heights with the development of long-range bombers and fighter jets that incorporated advanced aerodynamic shapes and powerful turbojet engines.

This era not only showcased the engineering prowess of the time but also laid the groundwork for post-war commercial aviation, leading to the introduction of iconic aircraft such as the Boeing 707 and the Douglas DC-8.

Advancements in Materials and Manufacturing

The materials used in aircraft construction have undergone significant transformations over the decades, directly influencing performance, weight, and fuel efficiency. Early aircraft were primarily constructed from wood and fabric, which limited their speed and payload capacity. However, as technology progressed, engineers began to explore new materials that could withstand the rigors of flight while offering improved performance characteristics.

The introduction of aluminum alloys revolutionized aircraft manufacturing in the mid-20th century, providing a lightweight yet strong alternative that became the standard for commercial aviation. In recent years, advancements in composite materials have further transformed aircraft design. Carbon fiber reinforced polymers (CFRP) are now widely used in modern airliners due to their exceptional strength-to-weight ratio and resistance to corrosion.

For instance, the Boeing 787 Dreamliner features approximately 50% composite materials in its structure, significantly reducing its overall weight and improving fuel efficiency. Additionally, advancements in manufacturing techniques such as additive manufacturing (3D printing) are reshaping how components are produced. This technology allows for complex geometries that were previously impossible to achieve with traditional manufacturing methods, leading to lighter parts with enhanced performance characteristics.

Aerodynamics and Performance Enhancements

| Parameter | Description | Typical Value | Impact on Performance |

|---|---|---|---|

| Drag Coefficient (Cd) | Measure of aerodynamic drag of a vehicle | 0.25 – 0.35 | Lower Cd reduces air resistance, improving fuel efficiency and top speed |

| Lift Coefficient (Cl) | Measure of lift force generated by aerodynamic surfaces | -0.1 to 0.3 (negative for downforce) | Negative Cl increases downforce, enhancing grip and cornering stability |

| Frontal Area (A) | Projected area facing the airflow | 2.0 – 3.0 m² | Smaller frontal area reduces drag, improving acceleration and efficiency |

| Downforce (N) | Vertical force pushing the vehicle onto the road | 500 – 1500 N at 100 km/h | Increases tire grip, allowing higher cornering speeds |

| Weight Reduction (kg) | Reduction in vehicle mass through materials and design | 50 – 200 kg | Improves acceleration, braking, and handling |

| Coefficient of Rolling Resistance (Crr) | Resistance caused by tire deformation | 0.007 – 0.015 | Lower Crr improves fuel economy and reduces energy loss |

| Active Aero Components | Adjustable aerodynamic elements like spoilers and flaps | Variable | Optimizes drag and downforce dynamically for performance and efficiency |

Aerodynamics plays a pivotal role in aircraft design, influencing everything from fuel efficiency to stability during flight. The study of airflow around an aircraft has led to numerous innovations aimed at reducing drag and improving lift. Early aerodynamic designs were often based on trial-and-error methods; however, with the advent of computational fluid dynamics (CFD), engineers can now simulate airflow patterns with remarkable accuracy.

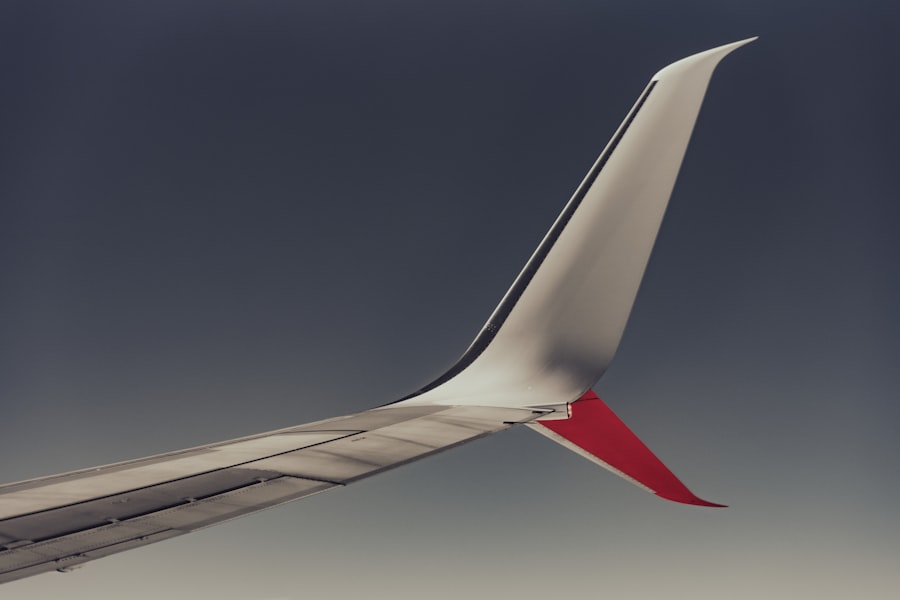

This technology allows for extensive testing of various shapes and configurations before physical prototypes are built, significantly reducing development time and costs. One notable example of aerodynamic innovation is the development of winglets—small vertical extensions at the tips of wings that reduce induced drag. Winglets have become a common feature on modern airliners, contributing to fuel savings of up to 5%.

Additionally, advancements in variable geometry wings have allowed for improved performance across different flight regimes. Aircraft like the Concorde utilized variable-sweep wings to optimize aerodynamics during takeoff, cruise, and landing phases. These enhancements not only improve operational efficiency but also contribute to overall passenger comfort by reducing turbulence during flight.

Integration of Technology in Aircraft Design

The integration of advanced technology into aircraft design has transformed how engineers approach the development process. Modern aircraft are equipped with sophisticated avionics systems that enhance navigation, communication, and safety. Fly-by-wire technology has replaced traditional mechanical control systems with electronic interfaces that provide pilots with greater precision and responsiveness.

This shift has not only improved handling characteristics but has also enabled the implementation of advanced autopilot systems that can manage complex flight operations with minimal pilot intervention. Moreover, the rise of digital twin technology is revolutionizing how aircraft are designed and maintained. A digital twin is a virtual representation of an aircraft that simulates its performance under various conditions throughout its lifecycle.

This technology allows engineers to analyze data from real-world operations to optimize design features and predict maintenance needs proactively. For instance, airlines can use digital twins to monitor engine performance in real-time, identifying potential issues before they lead to costly downtime or safety concerns. The integration of such technologies not only enhances operational efficiency but also contributes to improved safety standards across the aviation industry.

Sustainability and Environmental Considerations

As concerns about climate change intensify, sustainability has become a central focus in aeronautical design. The aviation industry is under increasing pressure to reduce its carbon footprint while maintaining growth in air travel. Engineers are exploring various strategies to achieve this goal, including the development of more fuel-efficient engines and alternative fuels.

The introduction of sustainable aviation fuels (SAFs), derived from renewable sources such as plant oils or waste materials, represents a significant step toward reducing greenhouse gas emissions associated with air travel. In addition to alternative fuels, there is a growing emphasis on designing aircraft that minimize environmental impact throughout their lifecycle. This includes optimizing manufacturing processes to reduce waste and energy consumption as well as designing for recyclability at the end of an aircraft’s operational life.

For example, Airbus has committed to developing an eco-design approach that considers environmental factors from the initial concept stage through production and operation. By prioritizing sustainability in aeronautical design, engineers are not only addressing regulatory pressures but also responding to consumer demand for greener travel options.

Safety and Ergonomics in Aircraft Engineering

Safety is paramount in aeronautical design, influencing every decision made during the engineering process. The aviation industry has established rigorous safety standards that dictate everything from structural integrity to emergency procedures. Engineers must consider potential failure modes and incorporate redundancy into critical systems to ensure that aircraft can operate safely under various conditions.

For instance, modern commercial airliners are equipped with multiple redundant systems for navigation and control, allowing pilots to maintain control even if one system fails. Ergonomics also plays a crucial role in aircraft design, particularly concerning cockpit layout and passenger comfort. The design of cockpit interfaces must facilitate intuitive operation while minimizing pilot workload during critical phases of flight.

This involves careful consideration of instrument placement, control accessibility, and information display formats. Similarly, passenger cabins are designed with comfort in mind; factors such as seat layout, cabin pressure, and noise reduction are all carefully engineered to enhance the flying experience. By prioritizing safety and ergonomics in aircraft engineering, designers contribute to both operational reliability and passenger satisfaction.

Future Trends in Aeronautical Design

Looking ahead, several trends are poised to shape the future of aeronautical design significantly. One prominent trend is the increasing focus on electric propulsion systems as a means to reduce emissions and noise pollution associated with traditional jet engines. Companies like Joby Aviation are developing electric vertical takeoff and landing (eVTOL) aircraft aimed at urban air mobility solutions that could revolutionize short-distance travel within cities.

Additionally, advancements in artificial intelligence (AI) are expected to play a transformative role in aeronautical design processes. AI algorithms can analyze vast amounts of data from flight operations to identify patterns that inform design improvements or operational efficiencies. Furthermore, machine learning techniques can enhance predictive maintenance strategies by analyzing historical data to forecast potential failures before they occur.

As global connectivity continues to expand, there will be an increasing demand for supersonic travel solutions that can significantly reduce flight times across long distances. Companies like Boom Supersonic are actively working on developing commercial supersonic jets that promise to make transcontinental travel faster while adhering to modern environmental standards. In summary, aeronautical design is an ever-evolving field characterized by innovation across multiple dimensions—from materials science to technological integration—while addressing pressing challenges such as sustainability and safety.

As engineers continue to push boundaries in this dynamic discipline, the future holds exciting possibilities for how we will travel through the skies.