The aerospace industry is a complex and multifaceted field that encompasses the design, development, and production of aircraft, spacecraft, and related systems and equipment. At the heart of this industry lies a vast array of components that are critical to the functionality, safety, and efficiency of aerospace vehicles. These components range from the engines that propel aircraft to the intricate avionics systems that ensure navigation and communication.

Each component must meet stringent regulatory standards and performance criteria, as even the smallest failure can have catastrophic consequences in the high-stakes environment of aviation and space exploration. Aerospace components are not only vital for operational performance but also play a significant role in the overall economics of the aerospace sector. The materials used, the manufacturing processes employed, and the innovations integrated into these components can dramatically affect the cost, weight, and efficiency of aircraft and spacecraft.

As the industry continues to evolve, driven by technological advancements and increasing demand for air travel and space exploration, the development of aerospace components remains a dynamic area of research and innovation. Understanding these components is essential for grasping how they contribute to the broader goals of safety, efficiency, and sustainability in aerospace operations.

Key Takeaways

- Aerospace components rely on specialized materials and manufacturing methods to meet rigorous performance standards.

- Innovations in propulsion systems are enhancing efficiency and reducing environmental impact.

- Advances in avionics and communication systems improve navigation, safety, and real-time data exchange.

- Development of lightweight, high-strength structures contributes to fuel savings and increased payload capacity.

- Integration of advanced sensors and control systems enables smarter, more autonomous aerospace operations.

Materials and Manufacturing Techniques

The selection of materials for aerospace components is a critical factor that influences performance, weight, and durability. Traditionally, materials such as aluminum and titanium have been favored due to their favorable strength-to-weight ratios and resistance to corrosion. However, advancements in material science have led to the emergence of composite materials, which combine multiple substances to achieve superior properties.

Carbon fiber reinforced polymers (CFRP), for instance, are increasingly used in aircraft structures because they offer significant weight savings while maintaining high strength and stiffness. This shift towards composites is particularly evident in modern aircraft like the Boeing 787 Dreamliner, which utilizes CFRP extensively in its fuselage and wings. Manufacturing techniques have also evolved significantly in recent years.

Additive manufacturing, commonly known as 3D printing, has emerged as a revolutionary process that allows for the creation of complex geometries that were previously impossible or prohibitively expensive to produce using traditional methods. This technology enables rapid prototyping and customization of components, reducing lead times and costs. For example, GE Aviation has successfully employed additive manufacturing to produce fuel nozzles for jet engines, resulting in parts that are lighter and more efficient than their traditionally manufactured counterparts.

The integration of advanced manufacturing techniques not only enhances the performance of aerospace components but also contributes to more sustainable production practices by minimizing waste.

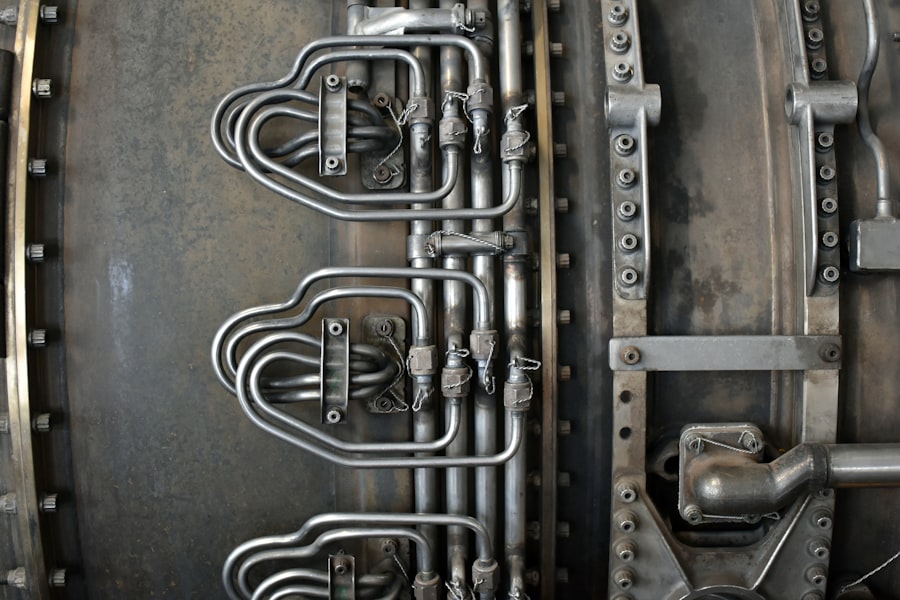

Innovations in Propulsion Systems

Propulsion systems are at the core of aerospace technology, providing the necessary thrust to lift vehicles off the ground and into the skies. Recent innovations in this area have focused on improving efficiency, reducing emissions, and enhancing overall performance. One notable advancement is the development of geared turbofan engines, which utilize a gear system to optimize the speed of the fan relative to the engine core.

This design allows for greater fuel efficiency and reduced noise levels compared to conventional turbofan engines. Pratt & Whitney’s PW1000G engine family exemplifies this innovation, offering airlines significant operational cost savings while meeting stringent environmental regulations. In addition to traditional jet engines, there has been a growing interest in alternative propulsion systems, particularly electric and hybrid-electric technologies.

These systems aim to reduce reliance on fossil fuels and lower greenhouse gas emissions associated with air travel. Companies like Airbus and Boeing are exploring hybrid-electric propulsion concepts that combine conventional engines with electric motors powered by batteries or fuel cells. The E-Fan X project by Airbus is a prime example of this trend, showcasing a hybrid-electric aircraft that aims to demonstrate the feasibility of electric flight for commercial applications.

As these technologies mature, they hold the potential to revolutionize how we think about propulsion in aviation.

Advancements in Avionics and Communication Systems

| Advancement | Description | Impact on Avionics | Key Metrics | Year Introduced |

|---|---|---|---|---|

| ADS-B (Automatic Dependent Surveillance-Broadcast) | Satellite-based surveillance technology that broadcasts aircraft position to ground stations and other aircraft. | Improved situational awareness and air traffic management. | Position update rate: 1 Hz; Range: 200+ nautical miles | 2000s |

| NextGen Communication Systems | Digital data link systems replacing traditional voice communication for air traffic control. | Enhanced communication clarity and reduced frequency congestion. | Data throughput: up to 31.5 kbps; Latency: < 1 second | 2010s |

| Integrated Modular Avionics (IMA) | Modular avionics architecture allowing multiple functions on shared hardware. | Reduced weight and maintenance costs, increased system flexibility. | Weight reduction: up to 30%; Mean Time Between Failures (MTBF): >10,000 hours | 2000s |

| Satellite Communication (SATCOM) | Global broadband communication enabling real-time data exchange and internet access. | Improved long-range communication and operational efficiency. | Data rates: up to 10 Mbps; Coverage: Global | 2010s |

| Fly-by-Wire Systems | Electronic flight control systems replacing mechanical linkages. | Enhanced flight safety, precision, and reduced pilot workload. | Response time: < 50 ms; System redundancy: 3-4 channels | 1980s-1990s |

| Wireless Avionics Intra-Communication (WAIC) | Wireless communication system within aircraft to reduce wiring complexity. | Weight savings and easier maintenance. | Frequency band: 4.2-4.4 GHz; Data rate: up to 10 Mbps | 2020s |

Avionics systems are essential for the safe operation of aircraft, encompassing everything from navigation and flight control to communication with air traffic control. Recent advancements in avionics technology have significantly enhanced situational awareness for pilots and improved overall safety in aviation operations. The introduction of glass cockpits—featuring digital displays that integrate multiple functions—has transformed how pilots interact with their aircraft’s systems.

These displays provide real-time data on flight parameters, navigation information, and system status, allowing for more informed decision-making during flight. Moreover, advancements in communication systems have facilitated more efficient air traffic management and improved connectivity for passengers. The implementation of satellite-based communication systems enables continuous tracking of aircraft in real-time, enhancing safety by providing air traffic controllers with accurate information about an aircraft’s position and trajectory.

Additionally, technologies such as Automatic Dependent Surveillance–Broadcast (ADS-B) allow aircraft to share their location with other nearby aircraft and ground stations, reducing the risk of mid-air collisions. As these technologies continue to evolve, they promise to further enhance safety and efficiency in air travel.

Development of Lightweight and High-Strength Structures

The quest for lightweight yet strong structures is a defining characteristic of modern aerospace engineering. Reducing weight is crucial for improving fuel efficiency and overall performance; therefore, engineers are continually seeking innovative solutions to achieve this goal. Advanced composite materials have become a cornerstone in this pursuit due to their exceptional strength-to-weight ratios.

For instance, the use of CFRP in wing structures allows for significant weight reductions while maintaining structural integrity under various load conditions. In addition to composites, innovative design techniques such as topology optimization are being employed to create structures that use material only where it is needed most. This computational design approach analyzes stress distribution within a component and suggests an optimal shape that minimizes weight without compromising strength.

The result is often a complex geometry that traditional manufacturing methods would struggle to produce but can be realized through advanced techniques like additive manufacturing. This synergy between material science and design innovation is paving the way for next-generation aerospace structures that are not only lighter but also more resilient.

Integration of Advanced Sensors and Control Systems

The integration of advanced sensors and control systems into aerospace components has revolutionized how aircraft operate and respond to various conditions during flight. Modern aircraft are equipped with an array of sensors that monitor everything from engine performance to environmental conditions outside the aircraft. These sensors provide critical data that informs flight control systems, enabling real-time adjustments to optimize performance and enhance safety.

One notable example is fly-by-wire technology, which replaces traditional mechanical control systems with electronic interfaces that interpret pilot inputs through sensors. This system allows for greater precision in controlling an aircraft’s movements while also incorporating safety features such as envelope protection—preventing pilots from exceeding safe operating limits. Additionally, advancements in artificial intelligence (AI) are being integrated into control systems to enhance decision-making capabilities during flight operations.

AI algorithms can analyze vast amounts of data from sensors to predict potential issues before they arise, allowing for proactive maintenance and improved safety outcomes.

Future Trends in Aerospace Component Technology

As we look toward the future of aerospace component technology, several trends are emerging that promise to shape the industry significantly. One such trend is the increasing focus on sustainability and environmental responsibility. With growing concerns about climate change and its impact on aviation, manufacturers are investing heavily in developing eco-friendly technologies.

This includes not only alternative propulsion systems but also sustainable aviation fuels (SAFs) derived from renewable sources that can significantly reduce carbon emissions compared to traditional jet fuels. Another trend is the continued integration of digital technologies into aerospace manufacturing processes. The adoption of Industry 4.0 principles—characterized by automation, data exchange, and smart manufacturing—will enable manufacturers to optimize production efficiency while maintaining high-quality standards.

Technologies such as the Internet of Things (IoT) will facilitate real-time monitoring of production processes, allowing for immediate adjustments based on data analytics. This shift towards digitalization will not only enhance operational efficiency but also enable more agile responses to market demands.

Impact of Advancements on Aerospace Industry

The advancements in aerospace component technology have far-reaching implications for the industry as a whole. Improved materials and manufacturing techniques lead to lighter, more efficient aircraft that consume less fuel and produce fewer emissions—an essential consideration as global air travel continues to grow. Innovations in propulsion systems not only enhance performance but also align with environmental goals by reducing reliance on fossil fuels.

Furthermore, advancements in avionics and communication systems contribute significantly to safety improvements within aviation operations. Enhanced situational awareness for pilots through advanced displays and real-time data sharing reduces the likelihood of accidents while improving overall operational efficiency. As these technologies continue to evolve, they will play a crucial role in shaping the future landscape of air travel.

In conclusion, the ongoing evolution of aerospace components reflects a commitment to innovation that addresses both current challenges and future opportunities within the industry. As manufacturers embrace new materials, advanced manufacturing techniques, and cutting-edge technologies, they pave the way for safer, more efficient, and environmentally responsible aviation practices that will define the next era of aerospace exploration and travel.