Continental Aerospace Technologies, a prominent player in the aviation sector, has established itself as a leader in the design and manufacture of aircraft engines and propulsion systems. With a rich history that dates back to the early 20th century, the company has continually evolved to meet the demands of an ever-changing aviation landscape. Its commitment to innovation and quality has made it a trusted name among aircraft manufacturers and operators worldwide.

The company’s extensive portfolio includes a range of piston engines, turbocharged engines, and advanced propulsion systems that cater to various segments of the aviation market, from general aviation to commercial and military applications. The significance of Continental Aerospace Technologies extends beyond its product offerings; it plays a crucial role in shaping the future of aviation. By investing in research and development, the company is at the forefront of technological advancements that enhance performance, efficiency, and safety in flight operations.

As the aviation industry faces challenges such as increasing fuel costs, environmental regulations, and the need for improved safety measures, Continental Aerospace Technologies is poised to lead the charge in developing solutions that address these issues while maintaining high standards of reliability and performance.

Key Takeaways

- Continental Aerospace Technologies plays a pivotal role in advancing aircraft engine technology.

- Innovations in propulsion systems have significantly improved aircraft performance and efficiency.

- The use of cutting-edge materials and manufacturing processes enhances engine durability and reduces weight.

- Advances in avionics and navigation systems contribute to safer and more precise flight operations.

- Continental Aerospace Technologies is committed to environmental sustainability and shaping the future of aviation.

Evolution of Aircraft Engines

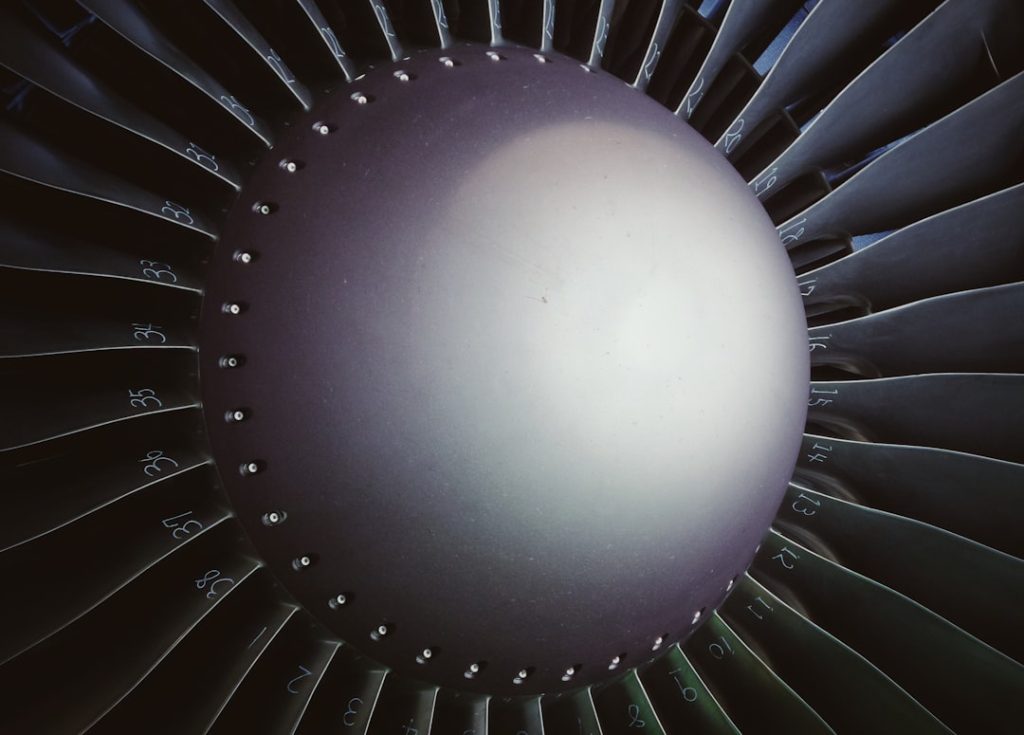

The evolution of aircraft engines is a fascinating journey that reflects the broader advancements in technology and engineering. In the early days of aviation, engines were primarily simple, air-cooled designs that relied on basic principles of internal combustion. These engines were often heavy and inefficient, limiting the performance and range of early aircraft.

However, as aviation technology progressed through the decades, so too did the complexity and efficiency of aircraft engines. The introduction of liquid-cooled engines in the 1920s marked a significant turning point, allowing for greater power output and improved thermal management. The post-World War II era saw a dramatic shift with the advent of turbojet engines, which revolutionized commercial aviation by enabling faster speeds and higher altitudes.

This transition was not merely a technological upgrade; it represented a paradigm shift in how aircraft were designed and operated. The introduction of turbofan engines further enhanced efficiency and reduced noise levels, making air travel more accessible and comfortable for passengers. Continental Aerospace Technologies has been instrumental in this evolution, continuously refining its engine designs to incorporate advanced materials and technologies that improve performance while reducing environmental impact.

Innovations in Aircraft Propulsion Systems

Innovations in aircraft propulsion systems have been pivotal in enhancing the overall efficiency and performance of modern aircraft. One notable advancement is the development of hybrid-electric propulsion systems, which combine traditional combustion engines with electric motors. This approach not only reduces fuel consumption but also minimizes emissions, aligning with global efforts to create more sustainable aviation solutions.

Continental Aerospace Technologies has been actively exploring hybrid technologies, recognizing their potential to transform the industry by offering quieter operations and lower operational costs. Another significant innovation is the integration of advanced control systems that optimize engine performance in real-time. These systems utilize sophisticated algorithms and data analytics to monitor various parameters such as temperature, pressure, and fuel flow, allowing for dynamic adjustments that enhance efficiency and safety.

By leveraging artificial intelligence and machine learning, Continental Aerospace Technologies is at the forefront of developing smart propulsion systems that can adapt to changing flight conditions, ultimately improving reliability and reducing maintenance costs.

Cutting-edge Materials and Manufacturing Processes

| Material/Process | Key Characteristics | Applications | Advantages | Challenges |

|---|---|---|---|---|

| Graphene | Single layer carbon atoms, high strength, excellent conductivity | Electronics, sensors, composites | Lightweight, strong, flexible, conductive | Scalability, cost, integration into devices |

| 3D Printing (Additive Manufacturing) | Layer-by-layer material deposition, complex geometries | Prototyping, aerospace, medical implants | Customization, reduced waste, rapid production | Material limitations, surface finish, speed |

| Carbon Fiber Reinforced Polymers (CFRP) | High strength-to-weight ratio, corrosion resistance | Aerospace, automotive, sports equipment | Lightweight, durable, fatigue resistant | Cost, repair difficulty, recycling |

| Metal Matrix Composites (MMC) | Metal base with ceramic or fiber reinforcement | Automotive, aerospace, electronics | Improved strength, thermal stability, wear resistance | Manufacturing complexity, cost |

| Nanomaterials | Materials with structures sized 1-100 nm | Medicine, electronics, energy storage | Unique optical, electrical, mechanical properties | Health risks, environmental impact, regulation |

| Laser Additive Manufacturing | Laser-based melting and fusing of powders | Aerospace, medical implants, tooling | High precision, complex parts, material efficiency | Equipment cost, process control, residual stress |

The aerospace industry has always been at the cutting edge of materials science, with manufacturers constantly seeking lighter, stronger, and more durable materials for aircraft components. Continental Aerospace Technologies has embraced this challenge by investing in research into advanced composite materials and alloys that offer superior performance characteristics. For instance, carbon fiber reinforced polymers (CFRPs) are increasingly being used in engine components due to their high strength-to-weight ratio and resistance to corrosion.

These materials not only contribute to weight savings but also enhance fuel efficiency by allowing for more aerodynamic designs. In addition to material innovations, manufacturing processes have also evolved significantly. The adoption of additive manufacturing, commonly known as 3D printing, has transformed how components are produced.

This technology allows for complex geometries that were previously impossible to achieve with traditional manufacturing methods. Continental Aerospace Technologies has implemented additive manufacturing techniques to produce engine parts with reduced waste and shorter lead times. This shift not only streamlines production but also enables rapid prototyping and customization, allowing for quicker responses to market demands.

Advancements in Avionics and Navigation Systems

The field of avionics has seen remarkable advancements over the past few decades, fundamentally changing how pilots interact with their aircraft. Modern avionics systems integrate multiple functions into a single interface, providing pilots with comprehensive situational awareness through advanced displays and data analytics. Continental Aerospace Technologies recognizes the importance of these systems in enhancing flight safety and efficiency.

By incorporating cutting-edge technologies such as synthetic vision systems and enhanced ground proximity warning systems, they are helping pilots make informed decisions during all phases of flight. Moreover, navigation systems have evolved from basic radio navigation aids to sophisticated satellite-based systems like Global Positioning System (GPS) and Automatic Dependent Surveillance–Broadcast (ADS-B). These technologies provide precise location data and improve air traffic management by enabling real-time tracking of aircraft positions.

Continental Aerospace Technologies is actively involved in integrating these advanced navigation capabilities into their aircraft systems, ensuring that operators benefit from enhanced accuracy and reliability during flight operations.

Environmental Sustainability in Aerospace Technologies

As global awareness of environmental issues grows, the aerospace industry faces increasing pressure to adopt sustainable practices. Continental Aerospace Technologies is committed to reducing its environmental footprint through various initiatives aimed at improving fuel efficiency and minimizing emissions. One approach involves developing engines that operate on alternative fuels such as biofuels or hydrogen, which can significantly reduce greenhouse gas emissions compared to traditional aviation fuels.

The company is actively researching these alternatives to ensure compatibility with existing engine designs while maintaining performance standards. In addition to fuel innovations, Continental Aerospace Technologies is also focused on optimizing operational practices to enhance sustainability. This includes implementing more efficient flight planning tools that reduce unnecessary fuel consumption during flight operations.

By leveraging data analytics and machine learning algorithms, airlines can optimize routes based on real-time weather conditions and air traffic patterns, leading to reduced fuel burn and lower emissions. The company’s commitment to sustainability reflects a broader industry trend towards greener aviation solutions that prioritize environmental stewardship alongside operational efficiency.

Future Prospects and Developments in Continental Aerospace Technologies

Looking ahead, Continental Aerospace Technologies is poised for continued growth and innovation as it navigates an evolving aviation landscape. The company is actively exploring opportunities in emerging markets such as urban air mobility (UAM) and electric vertical takeoff and landing (eVTOL) aircraft. These sectors represent significant potential for growth as urbanization increases demand for efficient transportation solutions within cities.

By leveraging its expertise in propulsion systems and avionics, Continental Aerospace Technologies aims to play a pivotal role in shaping the future of urban air transportation. Furthermore, advancements in artificial intelligence and machine learning are expected to drive significant changes in aircraft design and operation. Continental Aerospace Technologies is investing in research initiatives that explore how these technologies can enhance predictive maintenance capabilities, improve safety protocols, and streamline manufacturing processes.

As the industry embraces digital transformation, the company’s focus on integrating smart technologies into its products will be crucial for maintaining competitiveness in a rapidly changing market.

Impacts of Continental Aerospace Technologies on the Aviation Industry

The contributions of Continental Aerospace Technologies extend far beyond its product offerings; they have had a profound impact on the aviation industry as a whole. By consistently pushing the boundaries of innovation, the company has set new standards for performance, safety, and sustainability in aircraft propulsion systems. Its advancements have enabled airlines to operate more efficiently while reducing their environmental impact, aligning with global efforts to combat climate change.

Moreover, Continental Aerospace Technologies’ commitment to research and development has fostered collaboration across the industry, encouraging partnerships between manufacturers, airlines, and regulatory bodies. This collaborative approach has led to significant advancements in safety protocols and operational efficiencies that benefit all stakeholders involved in aviation. As the industry continues to evolve, the influence of Continental Aerospace Technologies will undoubtedly shape the future trajectory of aviation technology, ensuring that it remains at the forefront of innovation for years to come.