The aerospace industry is characterized by its stringent safety and performance standards, necessitating the continuous evolution of materials and technologies used in aircraft manufacturing and maintenance. One of the most innovative advancements in this sector is the development of antimicrobial coatings. These specialized coatings are designed to inhibit the growth of microorganisms, including bacteria, fungi, and viruses, on various surfaces within aircraft.

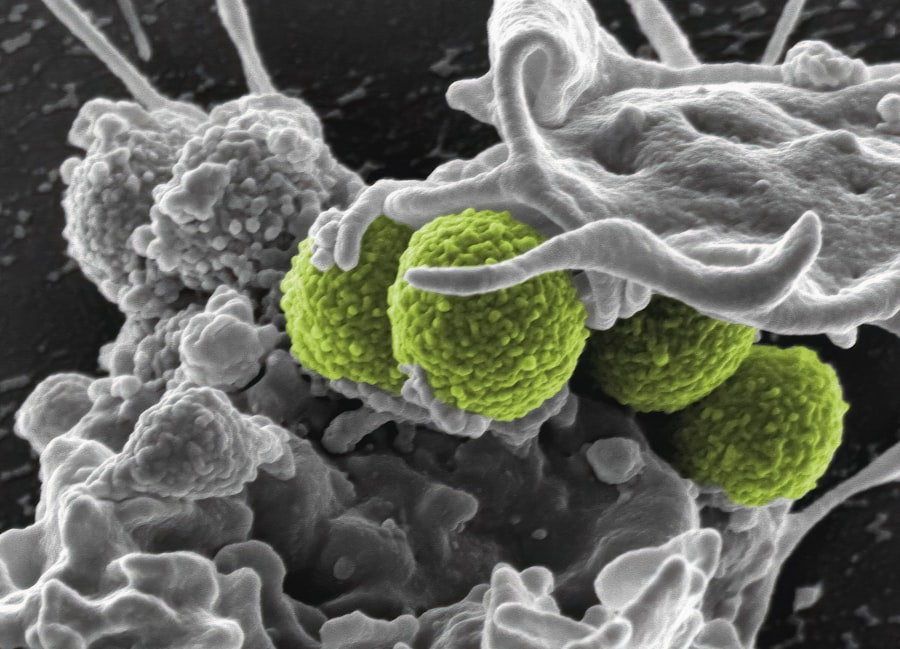

The significance of these coatings extends beyond mere aesthetics; they play a crucial role in enhancing passenger safety, improving hygiene, and reducing maintenance costs. Antimicrobial coatings are typically formulated with active agents that can either kill or inhibit the growth of pathogens upon contact. These agents can be embedded within the coating matrix or applied as a surface treatment.

In the context of aerospace applications, these coatings are particularly valuable in high-touch areas such as cabin interiors, lavatories, and food service areas, where the risk of microbial contamination is heightened. The integration of antimicrobial technology into aerospace materials not only addresses health concerns but also aligns with the industry’s commitment to sustainability and longevity, as these coatings can extend the lifespan of surfaces by protecting them from degradation caused by microbial activity.

Key Takeaways

- Aerospace antimicrobial coating is a specialized type of coating designed to inhibit the growth of microorganisms on surfaces in the aerospace industry, reducing the risk of contamination and infection.

- The market for aerospace antimicrobial coating is expected to experience significant growth due to increasing demand for air travel, rising concerns about hygiene and safety, and technological advancements in the industry.

- Key players in the aerospace antimicrobial coating market include companies such as AkzoNobel, PPG Industries, Sherwin-Williams, and Hentzen Coatings, with competition focused on product innovation and strategic partnerships.

- Antimicrobial coatings are applied in various aerospace applications, including cabin interiors, galleys, lavatories, and other high-touch surfaces to ensure a clean and safe environment for passengers and crew.

- The aerospace industry is subject to strict regulatory frameworks and industry standards, with antimicrobial coatings needing to meet specific requirements to ensure safety, efficacy, and environmental sustainability.

Market Analysis and Growth Trends

The market for aerospace antimicrobial coatings has witnessed significant growth in recent years, driven by increasing awareness of hygiene and safety in air travel. The COVID-19 pandemic has further accelerated this trend, as airlines and manufacturers seek to implement measures that reassure passengers about their safety during flights. According to industry reports, the global market for antimicrobial coatings in aerospace is projected to grow at a compound annual growth rate (CAGR) of over 10% from 2023 to 2030.

This growth is fueled by rising passenger numbers, expanding air travel networks, and a growing emphasis on maintaining clean environments in aircraft. In addition to the immediate impacts of the pandemic, long-term trends such as increasing passenger expectations for cleanliness and hygiene are shaping the market landscape. Airlines are investing in advanced technologies to enhance the passenger experience, and antimicrobial coatings are becoming a standard feature in new aircraft designs.

Furthermore, regulatory bodies are beginning to recognize the importance of these coatings in maintaining public health standards, which is likely to drive further adoption across the industry. As manufacturers continue to innovate and improve the efficacy of these coatings, their application will likely expand beyond traditional uses, creating new opportunities for growth.

Key Players and Competitive Landscape

The aerospace antimicrobial coating market is characterized by a diverse array of key players, ranging from established chemical manufacturers to specialized coating companies. Major corporations such as PPG Industries, AkzoNobel, and BASF have made significant investments in research and development to create advanced antimicrobial solutions tailored for aerospace applications. These companies leverage their extensive experience in materials science to develop coatings that not only provide antimicrobial properties but also meet the rigorous performance standards required in aviation.

In addition to these industry giants, several smaller firms and startups are emerging with innovative solutions that challenge traditional approaches. Companies like Microban International and Aculon are focusing on niche markets within the aerospace sector, offering unique formulations that cater to specific needs such as enhanced durability or eco-friendliness. The competitive landscape is further complicated by ongoing collaborations between manufacturers and research institutions aimed at developing next-generation antimicrobial technologies.

This dynamic environment fosters innovation and drives continuous improvement in product offerings, ultimately benefiting the aerospace industry as a whole.

Application of Antimicrobial Coating in Aerospace Industry

| Metrics | Value |

|---|---|

| Reduction in microbial contamination | Up to 99.9% |

| Increased durability of surfaces | Up to 5 years |

| Decrease in maintenance costs | Up to 30% |

| Improvement in overall hygiene | Significant |

The application of antimicrobial coatings in the aerospace industry spans a wide range of components and surfaces within an aircraft. One of the most critical areas is the cabin interior, where passengers frequently come into contact with surfaces such as armrests, tray tables, and seat belts. By applying antimicrobial coatings to these high-touch areas, airlines can significantly reduce the risk of pathogen transmission among passengers.

For instance, some airlines have begun incorporating these coatings into their cleaning protocols, ensuring that surfaces remain protected even between routine cleanings. Beyond passenger areas, antimicrobial coatings are also being utilized in aircraft maintenance and manufacturing processes. For example, components such as engine parts and fuel tanks can benefit from these coatings by preventing microbial-induced corrosion and biofilm formation.

This application not only enhances the longevity of critical components but also contributes to overall operational efficiency by reducing maintenance downtime. Furthermore, as aircraft manufacturers increasingly adopt lightweight materials such as composites, the need for protective coatings that offer both antimicrobial properties and weight savings becomes paramount.

Regulatory Framework and Industry Standards

The regulatory framework governing the use of antimicrobial coatings in the aerospace industry is complex and multifaceted. Various international organizations, including the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), set stringent guidelines for materials used in aircraft construction and maintenance. These regulations ensure that any coatings applied do not compromise safety or performance while providing necessary protection against microbial contamination.

In addition to aviation-specific regulations, antimicrobial coatings must also comply with broader health and safety standards established by organizations such as the Environmental Protection Agency (EPA) and the Centers for Disease Control and Prevention (CDC). These agencies evaluate the efficacy and safety of antimicrobial agents used in coatings to ensure they do not pose risks to human health or the environment. As awareness of public health issues continues to grow, it is likely that regulatory scrutiny will increase, prompting manufacturers to invest in compliance measures and certifications that demonstrate their commitment to safety.

Technological Advancements and Innovations

Technological advancements play a pivotal role in shaping the future of antimicrobial coatings within the aerospace sector. Recent innovations have focused on enhancing the effectiveness of these coatings while minimizing their environmental impact. For instance, researchers are exploring bio-based antimicrobial agents derived from natural sources such as plant extracts or essential oils.

These eco-friendly alternatives not only provide effective microbial protection but also align with the industry’s sustainability goals. Moreover, advancements in nanotechnology have led to the development of nanoscale coatings that offer superior antimicrobial properties. These coatings can be engineered at the molecular level to enhance their interaction with microorganisms, resulting in improved efficacy against a broader spectrum of pathogens.

Additionally, smart coatings equipped with self-cleaning properties are emerging as a promising solution for maintaining hygiene in aircraft interiors. These innovations represent a significant leap forward in antimicrobial technology, providing airlines with powerful tools to enhance passenger safety while addressing environmental concerns.

Regional Analysis and Market Opportunities

The aerospace antimicrobial coating market exhibits varying growth patterns across different regions due to factors such as air travel demand, regulatory environments, and technological adoption rates. North America currently holds a significant share of the market, driven by a robust aviation sector and increasing investments in advanced materials technology. Major airlines in this region are actively seeking innovative solutions to enhance passenger safety, creating ample opportunities for manufacturers of antimicrobial coatings.

In contrast, regions such as Asia-Pacific are experiencing rapid growth due to rising disposable incomes and expanding middle-class populations leading to increased air travel demand. Countries like China and India are investing heavily in their aviation infrastructure, presenting lucrative opportunities for antimicrobial coating suppliers looking to enter these emerging markets. Additionally, Europe remains a key player due to its stringent regulatory framework that encourages the adoption of advanced materials for safety purposes.

As global air travel continues to rebound post-pandemic, manufacturers must strategically position themselves to capitalize on regional trends and emerging opportunities.

Future Outlook and Market Forecast

Looking ahead, the future of aerospace antimicrobial coatings appears promising as industry stakeholders increasingly recognize their importance in ensuring passenger safety and enhancing operational efficiency. The market is expected to continue its upward trajectory, driven by ongoing innovations in coating technologies and growing consumer demand for hygienic travel experiences. As airlines prioritize cleanliness in their operations, investments in antimicrobial solutions will likely become a standard practice rather than an exception.

Furthermore, as regulatory bodies continue to evolve their guidelines surrounding health and safety standards in aviation, manufacturers will need to stay ahead of compliance requirements while delivering effective solutions. The integration of smart technologies into antimicrobial coatings may also pave the way for new applications beyond traditional uses, potentially transforming how aircraft interiors are maintained. Overall, the aerospace antimicrobial coating market is poised for sustained growth as it adapts to changing consumer expectations and technological advancements over the coming years.