The aerospace industry is undergoing a profound transformation, often referred to as the aerospace revolution. This shift is characterized by the integration of cutting-edge technologies, innovative materials, and advanced manufacturing processes that are reshaping how aircraft and spacecraft are designed, built, and operated. The convergence of these advancements is not only enhancing performance and safety but also making air travel more sustainable and accessible.

As we delve into the various facets of this revolution, it becomes evident that the future of aerospace is being defined by a blend of traditional engineering principles and modern technological breakthroughs. The aerospace revolution is driven by a multitude of factors, including the increasing demand for air travel, the need for more efficient and environmentally friendly transportation solutions, and the exploration of new frontiers in space. With global air traffic projected to double over the next two decades, the industry faces significant challenges in terms of capacity, emissions, and operational efficiency.

In response, aerospace companies are investing heavily in research and development to create innovative solutions that address these challenges while also pushing the boundaries of what is possible in aviation and space exploration.

Key Takeaways

- Aerospace is undergoing a revolution driven by cutting-edge technologies and innovative materials.

- UAVs, drones, and hypersonic flight are transforming both military and commercial aerospace sectors.

- AI and machine learning are enhancing design, safety, and operational efficiency in aerospace systems.

- Renewable energy and electric propulsion are paving the way for greener, more sustainable flight.

- 3D printing is revolutionizing manufacturing by enabling faster, cost-effective production of complex aerospace components.

Advanced Materials and Manufacturing Processes

One of the cornerstones of the aerospace revolution is the development of advanced materials that enhance the performance and durability of aircraft and spacecraft. Traditional materials such as aluminum and titanium are being supplemented or replaced by composites, ceramics, and other high-performance materials that offer superior strength-to-weight ratios, corrosion resistance, and thermal stability. For instance, carbon fiber reinforced polymers (CFRPs) are increasingly used in commercial aircraft like the Boeing 787 Dreamliner, where their lightweight properties contribute to significant fuel savings and reduced emissions.

In addition to advanced materials, innovative manufacturing processes are transforming how aerospace components are produced. Techniques such as automated fiber placement (AFP) and resin transfer molding (RTM) allow for more precise and efficient fabrication of complex structures. Furthermore, the adoption of digital twin technology enables manufacturers to create virtual replicas of physical assets, facilitating real-time monitoring and predictive maintenance.

This integration of advanced materials with state-of-the-art manufacturing processes not only enhances product performance but also streamlines production timelines and reduces costs.

Unmanned Aerial Vehicles (UAVs) and Drones

Unmanned Aerial Vehicles (UAVs), commonly known as drones, represent one of the most significant advancements in aerospace technology. Initially developed for military applications, UAVs have rapidly expanded into commercial and civilian sectors, offering a wide range of capabilities from aerial photography to agricultural monitoring. The versatility of drones has led to their adoption in various industries, including logistics, construction, and environmental monitoring.

For example, companies like Amazon are exploring drone delivery systems to enhance last-mile logistics, while agricultural firms utilize UAVs for precision farming techniques that optimize crop yields. The regulatory landscape surrounding UAVs is evolving as well, with governments worldwide recognizing their potential benefits while also addressing safety and privacy concerns. The Federal Aviation Administration (FAA) in the United States has implemented regulations that govern drone operations, ensuring that they can be integrated safely into national airspace.

As technology continues to advance, we can expect to see further innovations in UAV capabilities, such as improved autonomy through artificial intelligence and enhanced payload capacities that will expand their applications even further.

Hypersonic Flight and Space Travel

| Metric | Value | Unit | Description |

|---|---|---|---|

| Speed of Hypersonic Flight | Mach 5 to Mach 25 | Mach | Speed range defining hypersonic flight (5 times to 25 times the speed of sound) |

| Typical Orbital Velocity | 7.8 | km/s | Speed required to maintain low Earth orbit |

| Re-entry Temperature | 1,650 to 2,200 | °C | Surface temperature experienced by spacecraft during atmospheric re-entry |

| Altitude for Hypersonic Flight | 20 to 100 | km | Typical altitude range for hypersonic vehicles in the atmosphere |

| Typical Spacecraft Launch Mass | 2,000 to 10,000 | kg | Mass range for small to medium-sized spacecraft |

| Duration of Hypersonic Flight Tests | 5 to 20 | minutes | Typical duration of hypersonic flight test missions |

| Heat Shield Thickness | 5 to 15 | cm | Thickness range of ablative heat shields used in re-entry vehicles |

| Typical Space Travel Distance (LEO) | 200 to 2,000 | km | Altitude range for Low Earth Orbit missions |

Hypersonic flight—defined as travel at speeds greater than Mach 5—represents a frontier in aerospace technology that promises to revolutionize both air travel and space exploration. The potential for hypersonic vehicles to drastically reduce travel times has captured the imagination of researchers and engineers alike. For instance, a flight from New York to London could take less than an hour with hypersonic technology, compared to the typical seven hours for conventional commercial flights.

Companies like Boeing and Lockheed Martin are actively developing hypersonic prototypes that leverage advanced propulsion systems and aerodynamic designs to achieve these unprecedented speeds. In parallel with hypersonic flight advancements, space travel is experiencing a renaissance fueled by both governmental space agencies and private enterprises. The emergence of companies like SpaceX has dramatically reduced the cost of launching payloads into orbit while also paving the way for human spaceflight beyond low Earth orbit.

The development of reusable rocket technology has been a game-changer; SpaceX’s Falcon 9 rocket can be launched multiple times with minimal refurbishment, significantly lowering launch costs. As we look toward the future, the combination of hypersonic flight capabilities and advancements in space travel could lead to a new era of global connectivity and exploration beyond our planet.

Artificial Intelligence and Machine Learning in Aerospace

Artificial intelligence (AI) and machine learning (ML) are becoming integral components of modern aerospace systems, enhancing everything from design processes to operational efficiency. AI algorithms can analyze vast amounts of data generated by aircraft systems in real-time, enabling predictive maintenance that anticipates potential failures before they occur. This capability not only improves safety but also reduces downtime and maintenance costs for airlines.

For example, Delta Airlines has implemented AI-driven analytics to optimize flight schedules based on historical data, weather patterns, and passenger demand. Moreover, AI is playing a crucial role in autonomous flight systems. The development of fully autonomous aircraft is on the horizon, with companies like Boeing and Airbus investing in research to create pilotless commercial airliners.

These aircraft would rely on sophisticated AI systems to navigate complex airspace environments while ensuring passenger safety. The implications of such advancements extend beyond operational efficiency; they could also address pilot shortages by reducing reliance on human operators in certain flight scenarios.

Renewable Energy and Electric Propulsion Systems

As environmental concerns become increasingly pressing, the aerospace industry is exploring renewable energy sources and electric propulsion systems as viable alternatives to traditional fossil fuels. The aviation sector is responsible for a significant portion of global greenhouse gas emissions; therefore, transitioning to cleaner energy sources is imperative for sustainable growth. Electric propulsion systems are being developed for short-haul flights, with companies like magniX leading the charge by retrofitting existing aircraft with electric engines powered by batteries.

In addition to electric propulsion, hybrid systems that combine conventional engines with electric motors are gaining traction as a transitional solution. These hybrid systems can reduce fuel consumption and emissions while maintaining performance levels comparable to traditional aircraft. Furthermore, research into sustainable aviation fuels (SAFs) derived from renewable resources is underway, with airlines like United Airlines committing to using SAFs as part of their long-term sustainability goals.

The integration of renewable energy solutions into aerospace operations not only addresses environmental challenges but also positions the industry for future growth in an increasingly eco-conscious world.

3D Printing and Additive Manufacturing in Aerospace

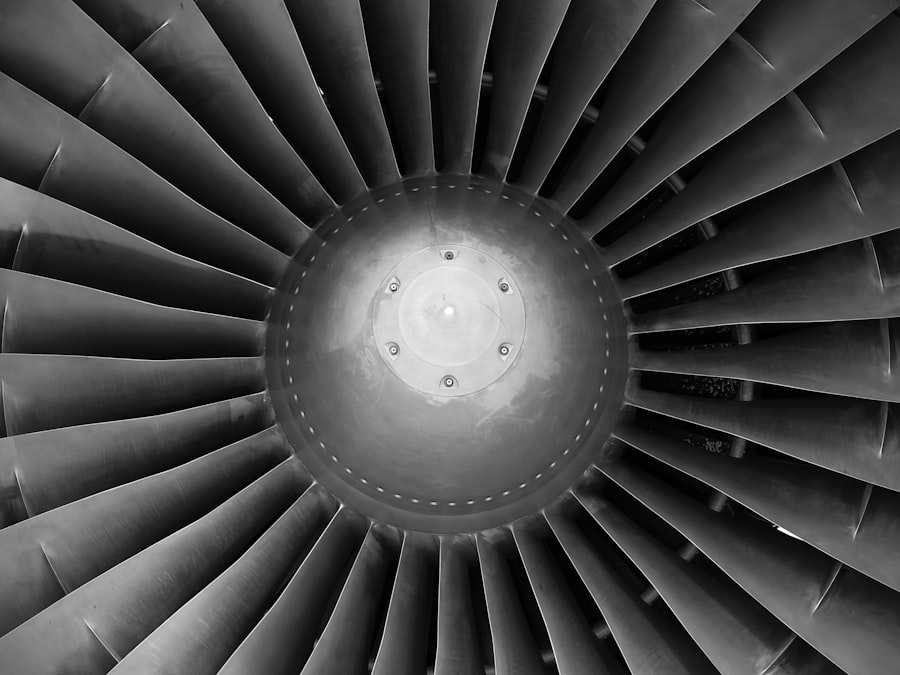

3D printing, or additive manufacturing, is revolutionizing the aerospace industry by enabling rapid prototyping and production of complex components with reduced waste. This technology allows engineers to create intricate designs that would be impossible or prohibitively expensive using traditional manufacturing methods. For instance, GE Aviation has successfully utilized 3D printing to produce fuel nozzles for jet engines that are lighter and more efficient than their traditionally manufactured counterparts.

The benefits of 3D printing extend beyond just weight reduction; it also allows for on-demand production of spare parts, which can significantly reduce inventory costs for airlines and manufacturers alike. In remote locations or during emergencies, having access to 3D printing capabilities can expedite repairs and minimize downtime. As additive manufacturing technology continues to evolve, we can expect even greater integration into aerospace supply chains, leading to more agile production processes that respond quickly to changing market demands.

Future Outlook and Implications for the Aerospace Industry

The future outlook for the aerospace industry is one marked by innovation and transformation across multiple dimensions. As advanced technologies continue to emerge, they will redefine not only how aircraft are designed and manufactured but also how they operate within an increasingly complex global airspace system. The integration of AI, advanced materials, renewable energy solutions, and autonomous systems will create a more efficient and sustainable aviation ecosystem.

However, this rapid evolution also presents challenges that must be addressed through collaboration among industry stakeholders, regulatory bodies, and governments. Ensuring safety while embracing innovation will require robust frameworks that adapt to new technologies without stifling progress. Additionally, workforce development will be crucial as new skills become necessary in an industry increasingly reliant on digital technologies.

As we look ahead, it is clear that the aerospace revolution is not merely about technological advancements; it encompasses a broader vision for a more connected world where air travel is safer, more efficient, and environmentally responsible. The implications of these changes will resonate far beyond the aerospace sector itself, influencing global trade patterns, economic development, and even our understanding of what it means to explore beyond our planet.